- CFD, Fluid Flow, FEA, Heat/Mass Transfer

Fluid Mechanics & Heat Transfer

Textbook Solutions: Fluid Mechanics, Heat & Mass Transfer, Aerodynamics

FM, HTX, MTX, AERO, COMBUSTION

This page is being continuously updated with complex (text-book type) problems in Fluid Mechanics, Heat Transfer, Aerodynamics, Mass Transfer, Combustion and Thermodynamics. The solutions to compressible flows including sub-sonic, sonic and supersonic flows inside a converging-diverging nozzle will be presented.

Table of Contents:

Buoyancy \-\ Plug Flow between Parallel Plates \-\ Flow through Pipe Branches forming Tee or Wye Network \-\ Equation of State: Soave-Redlick-Kwong Equation \-\ Half Filled Rotating Tube \+\ Thermal Network Example Calculations \=\ Steps to Create a Thermal Network Solver \=\ TNSolver Examples \=\ Fluid Network Solver \+\ Hardy-Cross Method Example \/\ Example: 3-Reservoirs System

Newton-Raphson Method \/\ Example Validation Cases \:\ Basic Fluid Network Solver \=\ Helper Functions to Develop the Solver in Java \=\ Fixed-flow and Pressure-jump Example: Python \:\ Fixed-flow and Pressure-jump Example: Java \+\ User Guide and Limitation of the Network Solver \@\ Sample Java Code based on Picard IterationsSummary of Hydrostatics

- For a plane surface immersed in a liquid in any orientation, the total normal pressure over the surface is P = A * ρ * g * h where h is the vertical depth of the centre of the gravity of the surface from free surface of the liquid, A is area of the surface.

- A plane surface immersed in a liquid is acted upon by a system of parallel forces which can be reduced to act on a single point of the surface known as centre of pressure.

- A curved surface immersed in a liquid is not acted upon a "system of parallel forces" and hence in general they cannot be reduced to a single force.

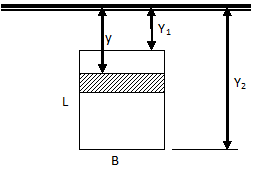

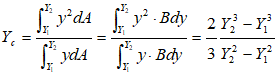

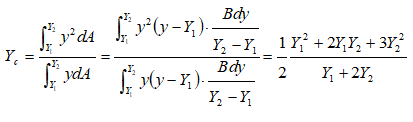

Centre of pressure of vertical rectangular plate

This is a very useful case which has frequent engineering applications.

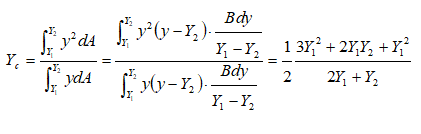

Similarly, for a triangular plate with base horizontal and at depth of Y2 and vertex up at depth of Y1, the centre of pressure is given by:

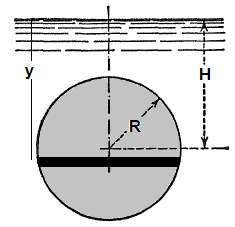

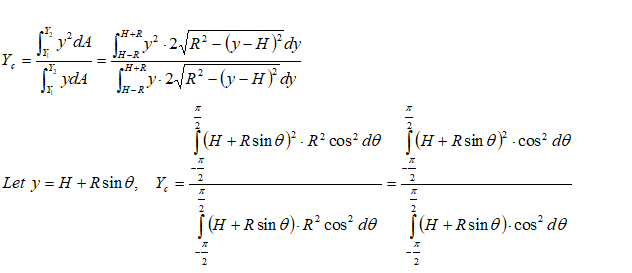

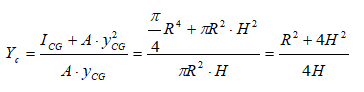

Centre of pressure of vertical circular plate

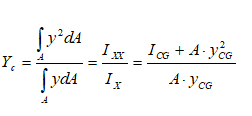

Even though the complicated definite integration is possible analytically, this is the time the introduce a simple method based on properties of sections. Note that the numerator of expression for centre of pressure is the "Second Moment of Inertia" or simply the Moment of Inertia about a "chosen axis" - typically the free surface of the liquid. The denominator is the "Moment of Area" about the same axis as chosen above - also known as "Statical Moment". Thus:

- If the area has axis of symmetry about the vertical axis, the centre of pressure will fall on it.

- Conversely, the centre of pressure will fall on the medial line, the vertical axis passing through the centre of gravity on the horizontal axis.

- The position of the centre of pressure is always below the centre of gravity of a surface.

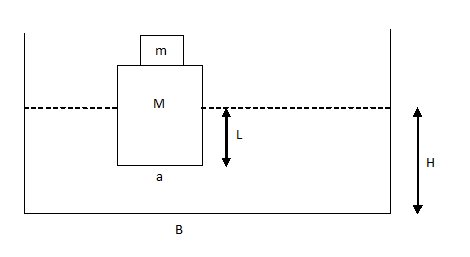

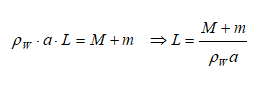

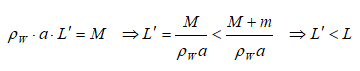

Buoyancy - Example Problem

A metallic block is floating along with a wooden block as shown in the figure below. If this metallic block falls into the tank, calculate the new depth of floatation and height of water level in the tank.

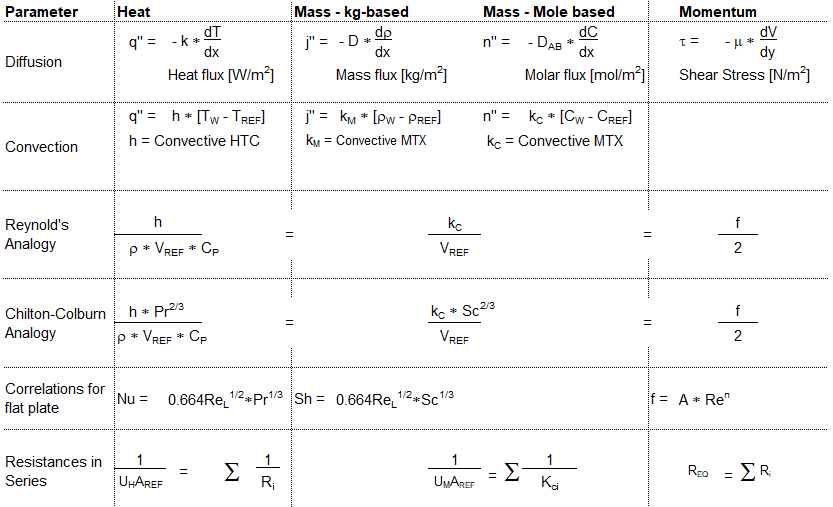

Analogy Between Fluid Flow, HTX and MTX

The method of relating two phenomena with some come feature is a powerful tool to both understand and remember the concepts. Following table summarizes key parameters which are analogous in the field of fluid flow (momentum transfer), heat transfer and mass transfer.

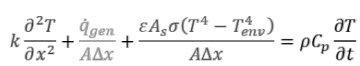

1D Heat Transfer with Convective Boundaries and Heat Generation

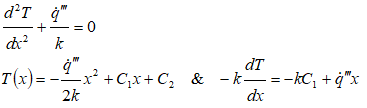

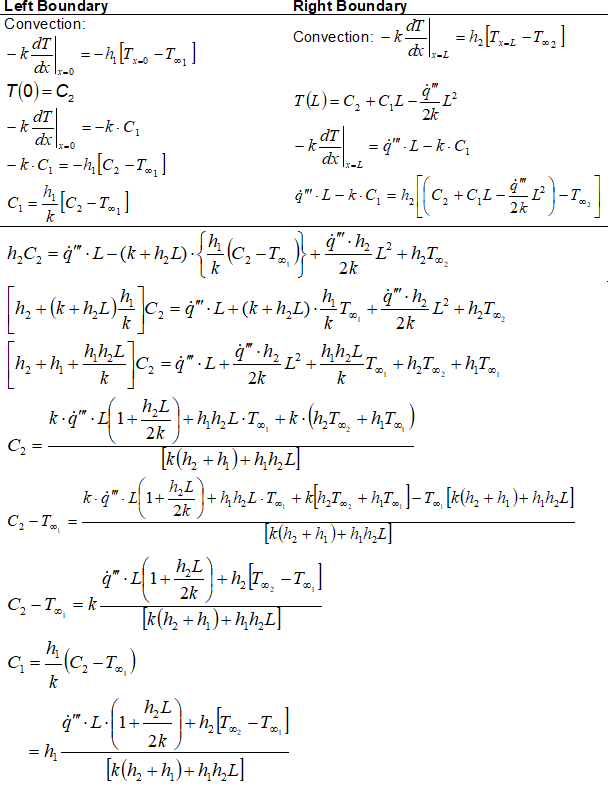

The designs of heat exchangers are the most predominant application of conductive heat transfer with such boundary conditions. The temperature profile in walls of a water-cooled internal combustion engine is also subject to this combination of boundary conditions though heat generation is not present in this application. Some applications can be current carrying conductor cooled by convection on both inner and outer diameters, nuclear fission in a annular cross-section cooled by convection on both the inner and outer radii. The governing equation and general solution of the differential equation is given by

Heat flow is assumed positive from left to right. Hence, the convective heat transfer on left face is negative if ambient temperature is < wall temperature on the left face!

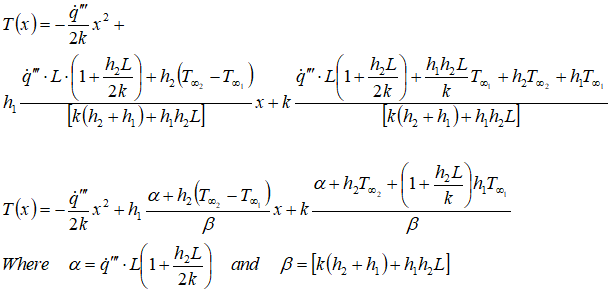

Finally, the temperature distribution function is expressed as:

Plug Flow between Parallel Plates

Flow in an Annular Passage

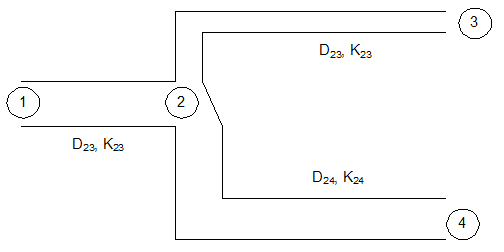

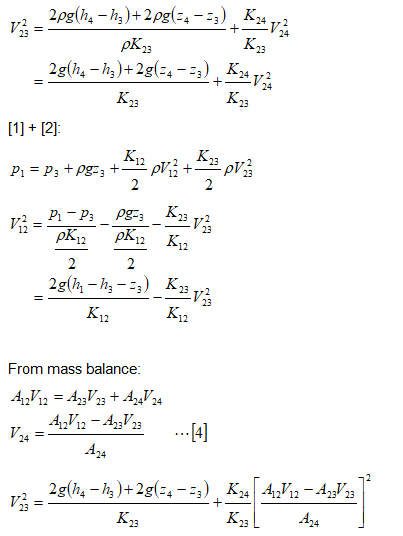

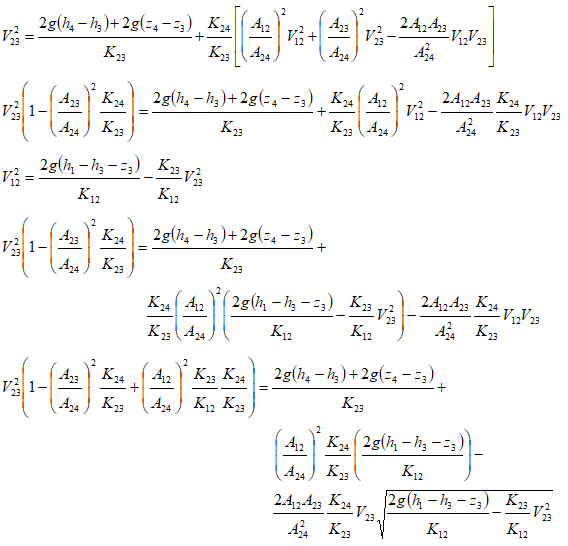

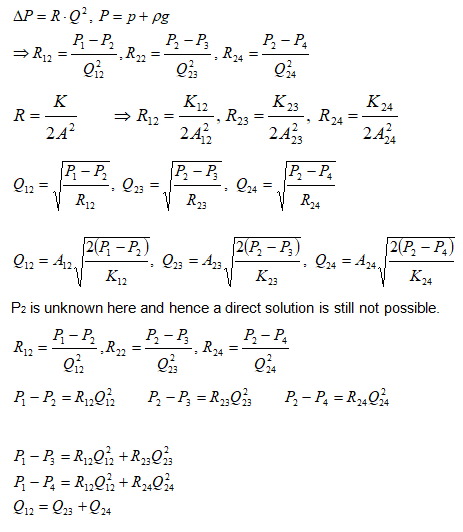

Flow through Pipe Branches forming Tee or Wye Network

Note velocities in pipe branches 1-2, 2-3 and 3-4 are not known in advance and hence the loss coefficients KMN cannot be adjusted to same velocity. Note that the junction losses at node 2 can be incorporated either in K12 or in K23 and K24. It is more convenient to club the node loss in K12 as appropriate assignment into K23 and K24 will involve extra calculations.

Denoting the pressures in terms of head of water column:

Simplifying further:

This is a non-linear equation in V23 and needs to be solved using trial-and-error or iterative approaches. Microsoft Excel Goal Seek utility can be used to solve this equation as well. A good initial guess would be required.

A more compact approach in terms of fluid resistances can be used as demonstrated below.

Thus, we have 3 equations and 3 unknowns – but they are still non-linear and needs to be solved using iterative method.

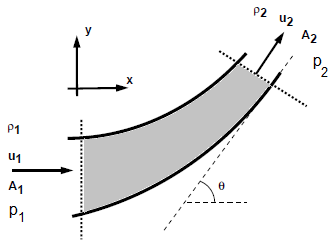

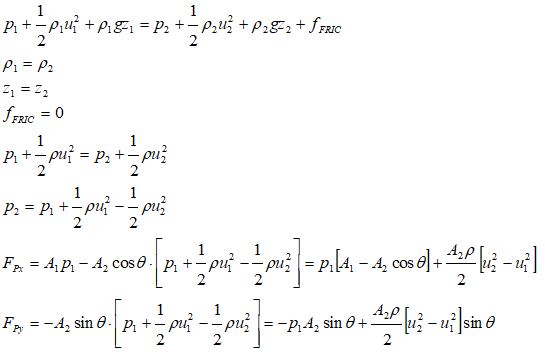

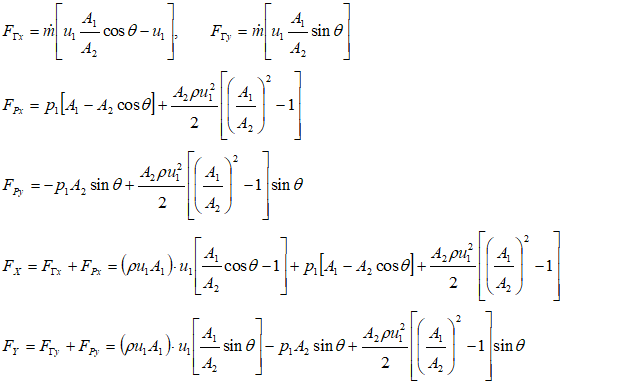

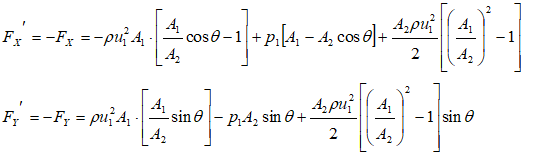

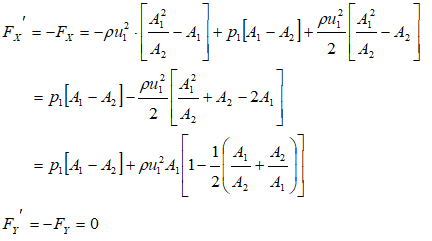

Force on a curved pipe with varying cross-section

A reducing bend having diameters D upstream and d downstream, has water flowing through it at the rate of m [kg/s] under a pressure of p1 bar. Neglecting any loss is head for friction calculate, the horizontal and vertical components of force exerted by the water on the bend.

Newton's Law of Motion applied to Fluid Elements:

F = m [u2 - u1]Newton's Third Law Applied to Pipe:

This is the force acting on the fluid and only means to apply the force on the fluid is the walls of the pipe. Hence, from Newton’s third law, and equation and opposite force will act on the pipe.

ΔΓX = m * [u2X - u1X] = FΓX. Thus: FΓX = m * [u2 cos(θ) - u1]ΔΓY = m * [u2Y - u1Y] = FΓY. Hence, FΓY = m * [u2 sin(θ) - 0] = m * u2 sin(θ)

Force on fluid element due to pressure at boundaries

FpX = p1A1 - p2A2cos(θ)FpY = 0 - p2A2sin(θ)

Use Bernoulli’s equation to find p2 in terms of other known parameters:

If pipe is straight

θ = 0

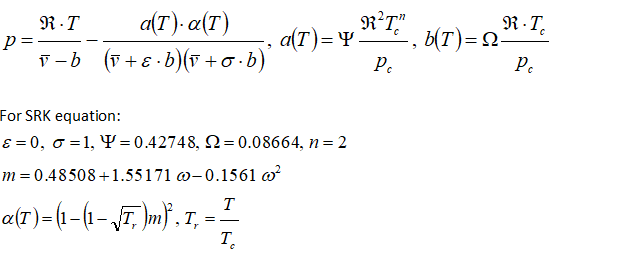

Equation of State: Soave-Redlick-Kwong Equation

or gases at very high pressure and those in liquid state such as Liquified Petrolium Gas (LPG), the accuracy of ideal gas equation falls sharply. Many improvizations have been made and SRK equation is one such method. The approach is demonstrated using following sample problem:

A gas cylinder with a volume of 5.0 m3 contains 44 kg of carbon dioxide at T = 273 K. estimate the gas pressure in [atm] using the SRK equation of state. Critical properties of CO2 and Pitzer acentric factor are: Tc = 304.2 K, pc = 72.9 atm, and ω = 0.225.

General cubic equation of state is given by following equation

Alternatively, the equation can be solved using Newton's method as described below.

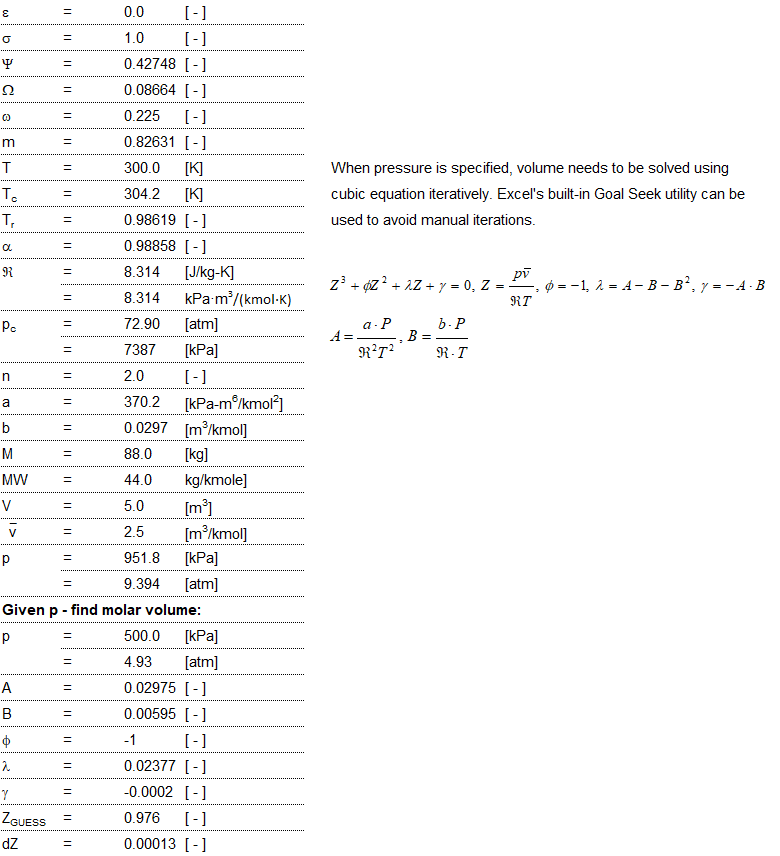

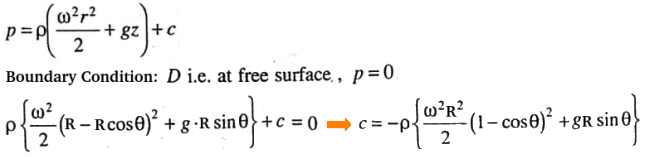

Hydrostatics in Rotating Reference Frame

The equation of equilibrium of fluid particles rotating about any fixed axis (say Z-axis) and acted about forces in 3 directions is given by:dp = ρ . {FX dx + FY dy + FZ dz + ω2(xdx + ydy)} where FX is the force per unit volume is X-direction. Alternatively, dp = ρ . {FX dx + FY dy + FZ dz + ω2rdr}. Any point where liquid separates is the location where pressure vanishes i.e. p = 0. Latus rectum of free surface = 2g/ω2.

Half Filled Rotating Tube: A circular tube is half full of liquid and is made to revolve around a vertical tangent line with angular velocity ω. If radius of the tube is R, calculate the angle between horizontal and diameter passing through the free surface of the liquid.

The tube is rotating about red line and the liquid level is shown by yellow zone. Point 'D' is the lower most point of free surface, θ is the angle which needs to be calculated.

The pressure at any location is given by: dp = ρ (ω2r.dr + gdz) where r is the distance of the point from the axis of rotation and z is the distance of the point from the origin. The point 'D' is rotating at radius r = R(1-cosθ), z = R.sinθ and is at p = 0. Another known point 'C' is at pressure zero, r = R(1+cosθ), z = -Rsinθ. Note that +z is along the downward direction (this is only a convention).

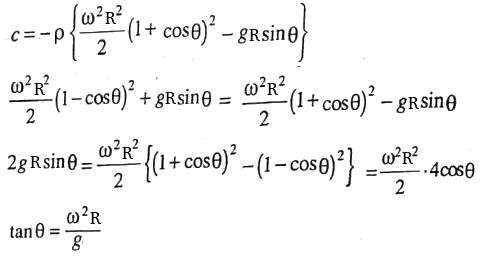

Liquid filled in rotating conical pot: A conical pot of height H and vertical (full cone) angle θ contains liquid k-times (x < 1) the volume of full cone. Find out the minimum angular velocity at which shall prevent liquid overflowing the cone.

Thus; z = (1-k).2H/3 ... [1] Also, from paraboloid of revolution (latus rectum): 2g/ω2 = R2/z ⇒ z = ω2.R2/2/g ... [2]

To prevent overflow: z ≤ (1-k).2H/3From equations [1] and [2], ω2.R2/2/g ≤ (1-k).2H/3 ⇒ ω ≤ [4g/3.(1-k).H/R2]1/2

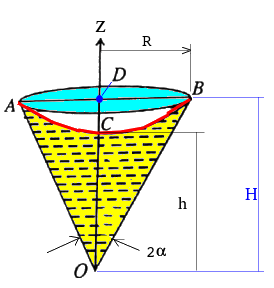

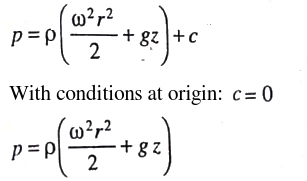

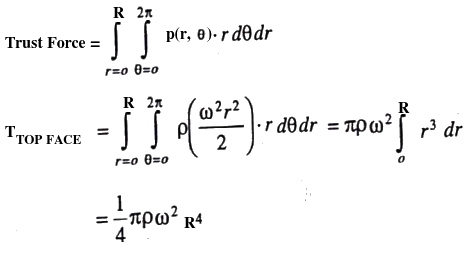

R = H . tan(α) ⇒ ω ≤ [4g/3H.(1-k)]1/2.cot(α), thus if k = 0.5, ω ≤ [2g/3H]1/2.cot(α)A closed circular cylinder is just filled with water and rotates about a vertical. Find the ratio of total thrust on the bottom to that on the top when the angular velocity is ω, H is the height and R the radius of the cylinder.

Fluid Pressure in Rotating Reference Frame

Bernoulli’s equation in the rotating frame where rotation is around z-axis: p(r, z) + ρgz + V(r) = p(r, z) + ρgz − ρω2r2. For a container open to atmosphere, gauge pressure at all points on the interface is zero i.e. p(r, z) = 0. Elevation of the free surface to the radial location: z = ω2r2/2/g.For a container rotating cylindrical about its axis: the shape of the free surface is a parabola and fluid inside the rotating cylinder forms a paraboloid of revolution, whose volume is one-half of the volume of the "circumscribing cylinder". To calculate angular velocity at which the liquid at the center reaches the bottom of the cylinder just as the liquid at the curved wall reaches the top of the cylinder: ωspill = (2gH)0.5/R.

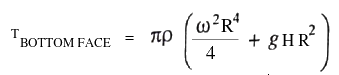

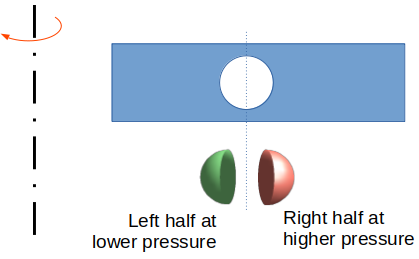

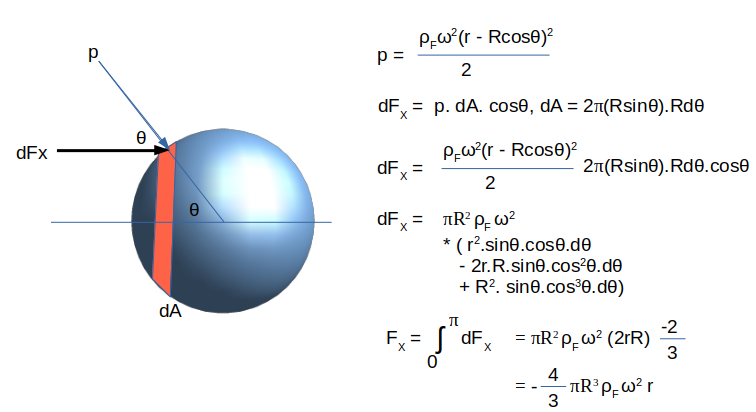

Ball in rotating tube

The centroid of a hemi-sphere is at 3R/8 from the base. Using this value, pressure on the left half of the ball = 1/2.ρF ω2(r-3R/8)2. The pressure on the right half of the ball = 1/2.ρF ω2(r+3R/8)2. Net force acting on the ball towards the axis of rotation = 1/2.ρF ω2(4.r.3R/8)2 × π*R2 where projected area = π*R2.

Net force due to fluid pressure towards axis of rotation, FF = 1/2.πR2.ρF ω2(r.3R/2) = 3/4πR3.ρF ω2r

Centrifugal force due to own mass of the ball, FB = 4/3.πR3.ρB ω2r

The position of the ball can be estimated using inequality FB ≤ FF. Will the ball get pushed towards inner radius for all densities of the ball? This method yeilded incorrect conclusion as the pressure on the surface of spherical ball was assumed to be varying linearly with radius instead of parabolic variation as per formula p(r) = p(r = r0) + 1/2.ρFω2r2. The correct derivation of net fluid forces acting on the ball are given below:

A circular cylinder of radius 'a' whose axis is vertical, is filled to depth h with homogeneous liquid of density ρ. Find the pressure as function of radial and vertical positions. Also, find the forces acting on the top lid if closed.

dp = ρ{-g.dz + ω2rdr} -> p = ρ{-g.z + 1/2.ω2r2} + C

Applying boundary condition at centre of top surface, p = 0 at r = 0 and z = h, C = ρgh. Thus, p = ρ{-g.z + 1/2.ω2r2} + ρgh and pressure at any point on top lid can be found by z = h. The thrust on the top lid is:

A hollow cone nearly filled with water, rotates uniformly about its axis which is vertical, the vertex being uppermost. Find the total thrust on the base of the cone. 'a' is the radius of the base and 2α the vertical angle of the cone.

p = ρ{-g.z + 1/2.ω2r2} + ρgh

At the base of the cone, z = 0. Thus, p(z=0) = ρ{1/2.ω2r2} + ρgh

Practice Questions:

- A hollow sphere of radius 'R' is half-filled with liquid and is rotating at angular velocity ω about its vertical diameter. Find out the value of ω at which the lowest point of the sphere is just exposed. Answer: [2g/R]1/2.[2-41/3]-1/2. Hint: volume of water remains constant.

- A narrow annular horizontal tube of radius R containing liquid is filled to half of its circumference and is rotating about the vertical diameter with angular velocity ω. Calculate the value of angular velocity at which liquid will just separate. Answer: [2g/R]1/2. Hint: pressure will become zero at lowest point when liquid separates.

- A vertical inverted conical vessel (base at the top) of height 'h' and cone angle 2θ is half-filled with a liquid oil. Find out the maximum angular velocity ω at which the oil shall not overflow. Answer: [2g/3h]1/2.cot(θ) Hint: use latus rectum as defined earlier.

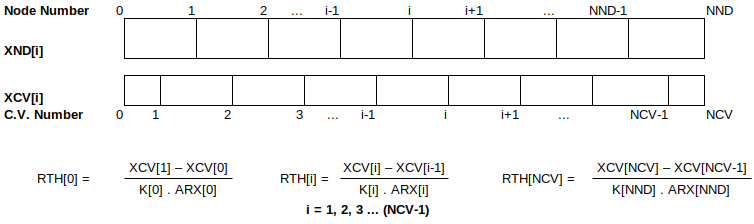

Steps to Create a Thermal Network Solver

Step-0: Define problem set-up: Steady or Transient, Initial Temperature, Total Run Time, Time Step Solution, Time Step Data Save.

Step-1: Define input table for the network. For Steady state cases, Cp and Mass shall be neglected.

Note that: NND = number of nodes, NCV = Number of control volumes = NND+1, XND[0] = XCV[0] = 0, XCV[i] = (XND[i+1] + XND[i] ) / 2 for i = 1 to NND-1, XCV[NCV] = XND[NND]. LCV[0] = XND[1]/2, LCV[i] = XCV[i] - XCV[i-1], LCV[NCV] = 0.5 x (XND[NND] - XND[NND-1])

| Node | T | ARX | Cp | Mass | Connected Nodes | ||

| [No.] | [C] | [m2] | [J/kg-K] | [kg] | [No.] | ||

| 1 | 0 | 0.01 | 2700 | 0.10 | 2 | 3 | - |

| 2 | 0 | 0.01 | 1200 | 0.05 | 1 | 3 | 4 |

| 3 | 40 | 0.01 | 1200 | 0.02 | 1 | 5 | 2 |

| 4 | 0 | 0.01 | 500 | 0.01 | 3 | - | - |

| ... | ... | ... | ... | ... | ... | ... | ... |

Step-2: Define resistance table. All information can be supplied as CSV file in following order (use negative number for boundary nodes). Here, Tref can be used to specified reference temperature for nodes with HTC boundary conditions as well as nodes with known or fixed temperatures. Value of 0 for Temperature or Tref indicate unknown or optional. There are some limitations to define the nodes such as a node must be placed where there is step change of cross-section. The node numbering must start with 1 and increase sequentially without any gap.

[3] [6]

| |

| |

[1]--------[2]------[5]-------[8]-------[9]-------[10]

| |

| |

[4] [7]

R_ID, s_node, e_node, xLen, xAr, k, Cp, Den

R01, 1, 2, 0.050, 0.0005, 200.0, 500.0, 2700.0

R02, 2, 3, 0.025, 0.0005, 200.0, 500.0, 2700.0

R03, 2, 4, 0.025, 0.0005, 200.0, 500.0, 2700.0

R04, 2, 5, 0.125, 0.0005, 200.0, 500.0, 2700.0

R05, 5, 6, 0.025, 0.0005, 200.0, 500.0, 2700.0

R06, 5, 7, 0.025, 0.0005, 200.0, 500.0, 2700.0

R07, 5, 8, 0.025, 0.0005, 200.0, 500.0, 2700.0

R08, 8, 9, 0.025, 0.0005, 200.0, 500.0, 2700.0

R09, 9, 10, 0.025, 0.0005, 200.0, 500.0, 2700.0

Use one line function to calculation thermal resistance and thermal inertia (capacitance) - lambda functions can also be used.

def calcThermalRes(xL, xA, xk): return xL/xA/xk def calcThermalIntertia(xL, xA, xDen, xCp): return xDen * (xL * xA) * xCpInputs for nodes, note that symbol Tref is used both for specified node temperature and reference temperature in case of convective boundary conditions.

NN stands for Node Number ------------------------- NN, Qdot, HTC, Tref 1, 0, 0, 288 2, 50, 0, 0 3, 50, 0, 0 4, 50, 0, 0 5, 0, 0, 0 6, 0, 0, 323 7, 0, 10, 298 8, 0, 10, 298 9, 0, 0, 0 10, 0, 0, 373

import csv

def csvToColumnLists(csv_file):

'''

Reads a CSV file and returns a dictionary where keys are column headers

and values are lists containing the data for each column. First non empty

row is assumed to be header containing strings without spaces. Header names

are case-sensitive.

'''

column_data = {}

with open(csv_file, 'r', newline='') as file_csv:

reader = csv.reader(file_csv)

headers = next(reader)

headers = [header.strip() for header in headers]

# Initialize empty list for each header and append data

for header in headers:

column_data[header] = []

for row in reader:

for i, value in enumerate(row):

column_data[headers[i]].append(value.strip())

return column_data

#

data_r = csvToColumnLists('thermal_r.csv')

node_col_1 = data_r['s_node']

node_col_2 = data_r['e_node']

node_col_1 = [int(NN) for NN in node_col_1]

node_col_2 = [int(NN) for NN in node_col_2]

xL = data_r['xLen']

# Find names of nodes as union of sets from column 2 and 3

NNU = list(set(node_col_1) | (set(node_col_2)))

NNU = [int(N) for N in NNU]

NNU.sort()

NNL = node_col_1 + node_col_2

max_n = int(max(set(NNL), key=NNL.count))

NNR = len(data_r['R_ID'])

NMAT = [[0] * max_n] * NNR

Create thermal resistance 2D array

def createRTH(xLen, xAr, xk, node_i, node_j):

'''

Create thermal resistance as 2D matrix, the size of matrix is 1 greater than

the maximum node number in the network. Note that node numbering starts from

1 and increase sequentially without any gap or step.

'''

NTH = int(max(max(node_i), max(node_j)))

NR = len(node_i)

RTH = []

for _ in range(NTH):

row = [0] * NTH

RTH.append(row)

for i in range(0, NR):

m = int(node_i[i]) - 1

n = int(node_j[i]) - 1

RTH[m][n] = float(xLen[i]) / float(xAr[i]) / float(xk[i])

RTH[n][m] = RTH[m][n]

return RTH

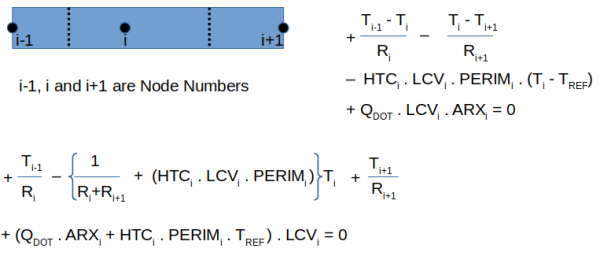

Step-3: Define governing equations using energy balance at each nodes with unknown temperatures and nodes with known temperatures.

For node-1 above: (T1 - T2)/R12 + (T1 - T3)/R13 = Qdot1

or

A1 T1 + B12T2 + B13T3 = Qdot1 where the second values in the subscripts correspond to entry under "Connected Nodes".

For node-2 above: (T2 - T1)/R12 + (T2 - T3)/R23 + (T2 - T4)/R24 = Qdot2

or

A2 T2 + B21T1 + B23T3 + B24T4 = Qdot2 where the second values in the subscripts correpond to entry under "Connected Nodes".

Step-4: Convert the individual equations into equivalent index notation (subscripts converted into indices of arrays).

Step-5: Define variables and arrays. NND = number of nodes, 1D arrays: XND[NND], XCV[NCV] Qdot[NND], Cp[NND], mass[NND], cond[NND], XAR[NND], LCV[NND]. 2D arrays: coeff_a[NND, NND], coeff_b[NND, NND], coeff_c[NND, NND], th_res[NND, 10], con_nodes(NND, 10). Each node is assumed to be connected to maximum 10 nodes.

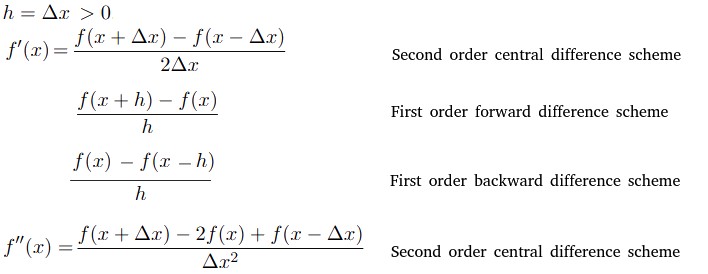

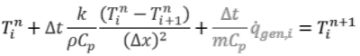

Write functions to approximate differential equations

For steady state 1D heat conduction with volumetric heat generation and convective heat loss:

Another example from web:

Training Project: Development of thermal network model and validation of results with 3D CFD simulations using ANSYS Fluent or OpenFOAM is a good internship project. This will impart not only programming skills but also help the engineer gain insight into heat transfer and matrix algebra.

Thermal Network Example Hand Calculations

Assume all heat flowing into a node is positive and all nodes around it are at higher temperatures. Final result will amend this assumption to correct values.q'[100W]----->[1]-------[2]--------[3]== T [300 K]

L: 0.10 [m]

A: 5E-4 [m2]

k: 50.0 [W/m-K]

Thermal Resistance: R12 = R23 = k/L/A = 4.0 [K/W]

Node-1: 1/R12 * [T2 - T1] = q' Node-2: 1/R12 * [T2 - T1] + 1/R23 * [T2 - T3] = 0 -1/R12 * [T1] + [1/R12 + 1/R23] * [T2] = T3/R23 -1/R12 * [T1] + [1/R12 + 1/R23] * [T2] = T3/R23

Matrix to solve

-1/R12 * [T1] + 1/R12 * [T2] = q' -1/R12 * [T1] + [1/R12 + 1/R23] * [T2] = T3/R23

Some other configurations that can serve as validation for any thermal network solver are:

q'[100 W]----->[1]-------[2]--------[3]== T [300 K]

|

|

[4]

q' [50 W]

HTC: 20 [W/m2-K], TREF=300 [K]

[5]

|

|

q'[100 W]----->[1]-------[2]--------[3]== T [300 K]

|

|

[4]

q' [50 W]

Generic node in a thermal network:

[s] [r] [p]

.' \ | /

' \ | /

' *[n]'-------- [m]

' |

` , |

` - =[u]

Assuming heat 'q' [W] is generated at node 'n' and all surrounding nodes are at lower temperatures:

[Tn - Tm]/RTH[n,m] + [Tn - Tp]/RTH[n,p] + ... + [Tn - Tu]/RTH[n,u] + h.A.[Tn - Tref] = q

{1/RTH[n,m] + 1/RTH[n,p] + ... + 1/RTH[n,u] + h.A}*Tn - 1/RTH[n,m]*Tm - ... - 1/RTH[n,u]*Tu = q + h.A.TrefΣj(1/RTH[n, j]) . Tn - {Σj[1/RTH[n,j] . Tj} = q + h.A.Tref ... ... ...[1]

In terms of thermal conductances:Σj(CTH[n, j]) . Tn - {Σj[CTH[n,j] . Tj} = q + h.A.Tref ... ... ...[2]

Next step: create thermal resistance 2d array. RTH[j,k] are calculated earlier and known for all j and k - sparse symmetric matrix, RTH[j, k] = RTH[k, j] and diagonal entries = 0. Note that thermal resistances by definition are always positive, a negative value is used to indicate direction of heat transfer.

Thermal Resistance Array:

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

--------|-------|-------|-------|-------|-------|-------|-------|-------|-------|

1 0 | 0.50 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

2 0.50 | 0 | 0.25 | 0.25 | 1.25 | 0 | 0 | 0 | 0 | 0 |

3 0 | 0.25 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

4 0 | 0.25 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

5 0 | 1.25 | 0 | 0 | 0 | 0.25 | 0.25 | 0.25 | 0 | 0 |

6 0 | 0 | 0 | 0 | 0.25 | 0 | 0 | 0 | 0 | 0 |

7 0 | 0 | 0 | 0 | 0.25 | 0 | 0 | 0 | 0 | 0 |

8 0 | 0 | 0 | 0 | 0.25 | 0 | 0 | 0 | 0.25 | 0 |

9 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.25 | 0 | 0.25 |

10 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.25 | 0 |

The thermal conductance matrix is:

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

--------|-------|-------|-------|-------|-------|-------|-------|-------|-------|

1 0 | 2.0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

2 2.0 | 0 | 4.0 | 4.0 | 0.8 | 0 | 0 | 0 | 0 | 0 |

3 0 | 4.0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

4 0 | 4.0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

5 0 | 0.8 | 0 | 0 | 0 | 4.0 | 4.0 | 4.0 | 0 | 0 |

6 0 | 0 | 0 | 0 | 4.0 | 0 | 0 | 0 | 0 | 0 |

7 0 | 0 | 0 | 0 | 4.0 | 0 | 0 | 0 | 0 | 0 |

8 0 | 0 | 0 | 0 | 4.0 | 0 | 0 | 0 | 4.0 | 0 |

9 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.0 | 0 | 4.0 |

10 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.0 | 0 |

Next step: find out nodes with known temperature.

data_n = csvToColumnLists('thermal_n.csv')

node_nnum = data_n['NN']

node_nnum = [int(NN) for NN in node_nnum]

node_hgen = data_n['Qdot']

node_hgen = [float(x) for x in node_hgen]

node_htc = data_n['HTC']

node_htc = [float(x) for x in node_htc]

node_Tref = data_n['Tref']

node_Tref = [float(x) for x in node_Tref]

node_known_T = [

item_1 for item_1, item_2, item_3 in zip(node_nnum, node_htc, node_Tref)

if item_2 == 0 and item_3 != 0

]

Next step: create node connectivity matrix. The matrix of each node and connected nodes (the indices for summation over index i in equation above) except for those with known/specified temperatures, can be estimated as follows.

Node connectivity array:

2 | 1 | 3 | 4 | 5 |

3 | 2 | 0 | 0 | 0 |

4 | 2 | 0 | 0 | 0 |

5 | 2 | 6 | 7 | 8 |

7 | 5 | 0 | 0 | 0 |

8 | 5 | 9 | 0 | 0 |

9 | 8 | 10 | 0 | 0 |

[3] [6]

| |

| |

[1]--------[2]------[5]-------[8]-------[9]-------[10]

| |

| |

[4] [7]

Using Σj(CTH[n, j]) . Tn - {Σj[CTH[n,j] . Tj} = q + h.A.Tref ... ... ...[2]

Node-2: Generic internal Node connected with more than 1 node.

(C[2, 1] + C[2, 3] + C[2, 4] + C[2, 5]) * T[2]

- C[2, 3] * T[3]

- C[2, 4] * T[4]

- C[2, 5] * T[5]

= C[2, 1] * T[1] + q[2] + h[2] * A[2] * (T[2] - Tref[2])

A[0, 1]*T[2] + A[0, 2]*T[3] + A[0, 3]*T[4] + A[0, 4]*T[5] = B[1]

Node-3: Boundary Internal Node connected with 1 node but also to a virtual node due to HTC boundary conditions.

C[3, 2] * (T[3] - T[2]) = q[3] + h[3] * A[3] * (T[3] - Tref[3]) A[1, 0]*T[2] + A[1, 2]*T[3] = B[2]

Node-4: convection node

C[4, 2] * (T[4] - T[2]) = q[4] + h[4] * A[4] * (T[4] - Tref[4]) A[2, 0]*T[2] + A[2, 3]*T[4] = B[3]Node-5:

(C[5, 2] + C[5, 6] + C[5, 7] + C[5, 8]) * T[5]

- C[2, 5] * T[2]

- C[7, 5] * T[7]

- C[8, 5] * T[8]

= C[7, 5] * T[7] + q[5] + h[5] * A[5] * (T[5] - Tref[5])

A[3, 0]*T[2] + + A[3, 4]*T[5] + A[3, 6]*T[7] + A[3, 7]*T[8] = B[4]

Next step: generate coefficient matrix as per equation [1] above. Compute the number of nodes with unknown temperature from node connectivity matrix. The coefficient matrix A[i, j] would be of size N x N where N is number of rows in node connectivity array defined above. phi_T = [row[0] for row in node_con_array] to get first column which contains node numbers for which temperature needs to be calculated.

Note:

- Arrays start with index zero but the lowest item in node connectivity matrix may be any number ≥ 1

- Coefficient matrix cannot have any element on diagonal row = zero

- The thermal resistance values are linked to node numbers and stored as rows and columns defined by connected nodes

- Thermal resistance matrix contains 0 values and hence a check is required to calculate the inverse of thermal resistances

Get first column of each row as center node: row_i = node_con_mat[i]; n_num = row_i[0]

Inner Loop Loops over second item onwards on each row

Calculate diagonal item of coefficient matrix A[i, i]

The initial coefficient matrix is as follows. Note that the rows and columns corresponding to nodes with specified temperature are all not required for final matrix inversion (solution of temperature values). Also, the coefficient matrix need not be symmetric.10.8 | -4.0 | -4.0 | -0.8 | 0.0 | 0.0 | 0.0 | -4.0 | 4.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | -4.0 | 0.0 | 4.0 | 0.0 | 0.0 | 0.0 | 0.0 | -0.8 | 0.0 | 0.0 | 12.8 | -4.0 | -4.0 | 0.0 | 0.0 | 0.0 | 0.0 | -4.0 | 3.995 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | -4.0 | 0.0 | 7.995 | -4.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | -4.0 | 8.0 |

Computed value of {b} excluding for those with known T:

{b} = [626.0, 50.0, 50.0, 1292.0, 1.49, 1.49, 1492.0]Computed temperatures in [K]: for nodes in first column of node connectivity matrix above. Validation of result with hand calculation is in progress though values are very close to results produced by TNSolver (without HTC boundary conditions).

288.0 356.2 368.7 368.7 339.1 323.0 339.9 350.9 362.0 373.0The results match with TNSolver values when convection is removed from nodes. Further enhancements planned for this code are:

- Give option to provide default length, cross-section area, material (thermal conductivity) for all resistors

- Let user chose positive integers for numbering nodes and not enforcing start from 1 without any gap

- Check correctness of inputs such as missing values, string instead of numbers...

- Add radiative heat transfer from resistors

- Add radiative heat transfer from nodes

- Add convection from resistors

- Add transient calculations

- Allow comments

- Single input file

The code can also be used to solve electrical networks where thermal conductivity 'k' needs to be replaced by electrical conductivity 'σ'. RTH = L/k/A, REL = ρ.L/A = L/σ/A where electrical conductivity σ = 1/ρ, ρ = electrical resistivity.

The example demonstrated above is linear and explicit where all coefficients and constants are independent of field variable 'T'. In cases where thermal conductivity is function of temperature or heat generation rate is function of temperature or cases like radiation where heat transfer rate is not a linear function of temperature [\(Q=\epsilon A\sigma (T^{4}-T_{∞}^{4})\)], the simple matrix inversion methods like y = np.linalg.solve(A, b) does not work. \[h_{rad}=\frac{\epsilon \sigma (T_{i}^{4}-T_{∞}^{4})}{(T_{i}-T_{∞})}\] which can be simplified (still non-linear) to \(h_{rad}=\epsilon \sigma (T_{i}+T_{∞})(T_{i}^{2}+T_{∞}^{2})\) The method above assumes that the ambient behaves like a black body. In case of radiative heat exchange between two non-black (grey) bodies and reflections of radiation are not taken into account: \[Q_{ij}^{RAD} = ε_i ε_j\cdot A_i F_{ij} (T_{i}^{4}-T_{j}^{4})\] When reflection of radiations are taken into account, some of the radiation coming from surface i gets reflected by surface j. A part of this reflected energy shall end up on other surfaces, which in their turn (if grey) shall reflect some fraction of the incident radiation. Radiative heat exchange between grey bodies is calculated using two different methods: Gebhart method and the Oppenheim method (Net Radiant Method).An iterative method like Jacobi or Gauss-Seidel iteration is required. The coefficient matrix A should ideally be diagonally dominant for guaranteed convergence. In Jacobi iteration, the value of each \(x_{i}\) at the new iteration is computed using the formula:

$$x_{i}^{(k+1)}=\frac{b_{i}-\sum \limits _{j\ne i}a_{ij}x_{j}^{(k)}}{a_{ii}}$$def Jacobi(A, b, x_0, max_iter=100, tolerance=1.0e-6):

'''

x_0: Initial guess for the solution, numpy array

tolerance: Convergence criteria

max_iter: Maximum number of iterations to perform

Returns: the approximate solution [vector].

'''

# Initialize the solution vector

x = x_0.copy()

n = len(b)

for k in range(max_iter):

x_new = x.copy()

for i in range(n):

# Calculate the sum of row elements, excluding diagonal value

sum_row = 0

for j in range(n):

if i != j:

sum_row = sum_row + A[i, j] * x[j]

x_new[i] = (b[i] - sum_row) / A[i, i]

# Check for convergence, np.inf = Maximum absolute value

L2NORM_new = np.linalg.norm(x_new - x, ord=np.inf)

L2NORM_old = np.linalg.norm(x_new, ord=np.inf)

if (L2NORM_new / L2NORM_old) <= tolerance:

print(f"Solution converged after {k+1} iterations.")

return x_new

x = x_new

print(f"Converge could not be achieved within {max_iter} iterations.")

return x

Gauss-Seidel Method: The convergence is guaranteed if the matrix A is strictly diagonally dominant [magnitude of diagonal entry ≥ sum of the magnitudes of non-diagonal entries for each row] or symmetric positive definite [square matrix that is equal to its transpose]. The Gauss-Seidel method often converges faster than the Jacobi method by using updated values within the same iteration.

def GaussSeidel(A, b, x_0, max_iter=100, tolerance=1.0e-6, ):

A = np.array(A, dtype=float)

b = np.array(b, dtype=float)

x = np.array(x_0, dtype=float)

n = len(b)

for iter in range(max_iter):

x_old = np.copy(x)

for i in range(n):

sum_ax = np.dot(A[i, :i], x[:i]) + np.dot(A[i, i+1:], x_old[i+1:])

x[i] = (b[i] - sum_ax) / A[i, i]

if np.linalg.norm(x - x_old) < tolerance:

print(f"Convergence achieved after {iter + 1} iterations.")

return x

print(f"Run did not converge within {max_iter} iterations.")

return x

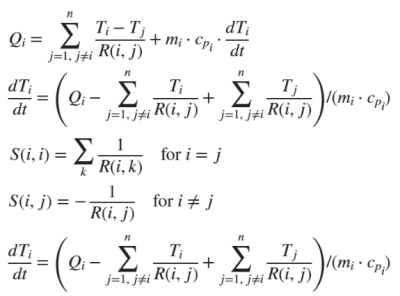

Finally, the most generic equation for thermal network solvers is derived below. Here, index 'i' is the node under iteration and 'j' refers nodes connected to it as described in node connectivity array, TA = ambient temperature, need not be same as RREF used for radiative heat transfer.

\(\sum\limits_{j} \left[ C_{ij} * (T_i - T_j) \right] + F_{ij} \cdot ε \cdot σ \cdot \sum\limits_{j} \left[ A_{ij} \cdot \left(\frac{(T_i + T_j)^4}{16} - T_{REF}^4 \right) \right] + \sum\limits_{j} \left[ h \cdot A_{ij} * \left( \frac{T_i + T_j}{2} - T_A \right) \right] = \dot{q}_i \)

\(\sum\limits_{j} \left[ C_{ij} * (T_i - T_j) \right] + F_{ij} \cdot ε \cdot σ \cdot \sum\limits_{j} \left[A_{ij} \cdot (\overline{T}_{ij}^2 - T_{REF}^2) \cdot (\overline{T}_{ij}^2 + T_{REF}^2) \right] + \sum\limits_{j} \left[h \cdot A_{ij} * \left(\frac{T_i + T_j}{2} - T_A\right) \right] = \dot{q}_i \)

Where \[\overline{T}_{ij} = \frac{T_i + T_j}{2}\]\(\sum\limits_{j} \left[ C_{ij} * (T_i - T_j) \right] + F_{ij} \cdot ε \cdot σ \cdot \sum\limits_{j} \left[A_{ij} \cdot (\overline{T}_{ij} - T_{REF}) \cdot (\overline{T}_{ij} + T_{REF}) \cdot (\overline{T}_{ij}^2 + T_{REF}^2) \right] + \sum\limits_{j} \left[h \cdot A_{ij} * (\overline{T}_{ij} - T_A) \right] = \dot{q}_i\)

\[ C_{RAD} = \underbrace{ (T_{REF}^2 + \overline{T}_{ij}^2) \cdot (\overline{T}_{ij} + T_{REF})}_\text{Non-linearity}\] \(\sum\limits_{j} \left[C_{ij} + F_{ij} ε \cdotσ \cdot \frac{A_{ij}}{2} \cdot C_{RAD} + h/2 \cdot A_{ij} \right ] \cdot T_i - \sum\limits_{j} \left(C_{ij} + F_{ij} ε \cdotσ \cdot \frac{A_{ij}}{2} \cdot C_{RAD} + h/2 \cdot A_{ij} \right) \cdot T_j = \dot{q}_i + \sum\limits_{j} F_{ij} \cdot ε \cdot σ \cdot A_{ij} \left[ T_{REF} \cdot C_{RAD} \right] + \sum\limits_{j} \left(h \cdot A_{ij} \cdot T_A \right) \)For 'i' defined in first column of node connectivity array above and 'j' varying from second column onwards for each 'i':

\[K_{ii}\cdot T_i + \sum\limits_{j}\left[K_{ij} \cdot T_j\right] = b_i \] where \[K_{ii} = \sum\limits_{j}\left[C_{ij} + F_{ij} ε \cdotσ \cdot \frac{A_{ij}}{2} \cdot C_{RAD} + h/2 \cdot A_{ij} \right ]\] \[ K_{ij} = - \left (C_{ij} + F_{ij} ε \cdotσ \cdot \frac{A_{ij}}{2} \cdot C_{RAD} + h/2 \cdot A_{ij} \right) \]Sample thermal network for a battery pack

[CON1+] [CON1-] [CON2+] [CON2-]

| | | |

|__[Case-top]__| |___[Case-top]__| ...other cells

| |

| |

[Cell-Z] [Cell-Z]

| |

| |

[Case]--[Gap-1]--[Can-1]--[C-1]--[Can-1]--[Gap-2]--[Can-2]--[C-2]--[Gap-3] ...other cells

| |

| |

[Cell-Z] [Cell-Z]

| |

| |

[Case-Bot] [Case-Bot] ...other cells

TNSolver Examples

Most of the examples in public domain are available through work published by Bob Cochran at Applied Computational Heat Transfer, Seattle, WA (TNSolver@heattransfer.org). Not much could be found in other sources. From user guide: plane wall with fixed temperature and convection boundary conditions.|```````| [in] [out]---[Tinf] h = 2.3 [W/m2-K] | | ``````` Begin Solution Parameters title = Simple Wall Model type = steady units = SI T units = C !Default is 'C', other options K, F, R End Solution Parameters Begin Conductors ! label type nd_i nd_j parameters wall conduction in out 2.3 1.2 1.0 ! k L A fluid convection out Tinf 2.3 1.0 ! h A End Conductors Begin Boundary Conditions ! type parameter node(s) fixed_T 21.0 in ! Inner wall T fixed_T 5.0 Tinf ! Fluid T End Boundary ConditionsDetailed output is in *.out file. The *.rst file contains:

time = 0

in 21

out 12.2727

Tinf 5

*.csv files contain

"label", "type", "nd_i", "nd_j", "T_i (C)", "T_j (C)", "Q (W)", "U (W/m^2-K)", "A (m^2)" "wall", "conduction", "in", "out", 21, 12.2727, 16.7273, 1.91667, 1 "fluid", "convection", "out", "Tinf", 12.2727, 5, 16.7273, 2.3, 1and

"label", "material", "volume (m^3)", "temperature (C)" "in", "N/A", 0, 21 "out", "N/A", 0, 12.2727 "Tinf", "N/A", 0, 5

Solution of the sample case described above (and used for Python scripting), in TNSolver without convection at nodes: note that TNSolver has option of specified temperature, heat flux, heat source and volumetric heat source at nodes. Convection can be specified on resistors only. Thus, tip convection can be applied using additional node to represent T∞ or the reference temperature for HTC.

Begin Solution Parameters

title = Simple Wall Model

type = steady

units = SI

T units = K !Default is 'C', other options K, F, R

End Solution Parameters

Begin Conductors

! label type nd_i nd_j parameters

R01 conduction N_01 N_02 200 0.050 0.0005 ! k L A

R02 conduction N_02 N_03 200 0.025 0.0005 ! k L A

R03 conduction N_02 N_04 200 0.025 0.0005 ! k L A

R04 conduction N_02 N_05 200 0.125 0.0005 ! k L A

R05 conduction N_05 N_06 200 0.025 0.0005 ! k L A

R06 conduction N_05 N_07 200 0.025 0.0005 ! k L A

R07 conduction N_05 N_08 200 0.025 0.0005 ! k L A

R08 conduction N_08 N_09 200 0.025 0.0005 ! k L A

R09 conduction N_09 N_10 200 0.025 0.0005 ! k L A

End Conductors

Begin Boundary Conditions

! type parameter node(s)

fixed_T 288 N_01

fixed_T 323 N_06

fixed_T 373 N_10

End Boundary Conditions

Begin Sources

! type parameter(s) node(s)

Qsrc 50.0 N_02

Qsrc 50.0 N_03

Qsrc 50.0 N_04

End Sources

Calculated temperature values in [K] are:

time = 0 N_01 288.0 N_02 355.9 N_03 368.4 N_04 368.4 N_05 338.2 N_06 323.0 N_07 338.2 N_08 349.8 N_09 361.4 N_10 373.0The result using Python code developed above and without heat transfer coefficient boundary at any node is given below. The values match with TNSolver and also demonstrates the fact that the effect of heat loss through convection at tip is negligible.

[288.0 355.9 368.4 368.4 338.2 323.0 338.2 349.8 361.4 373.0]

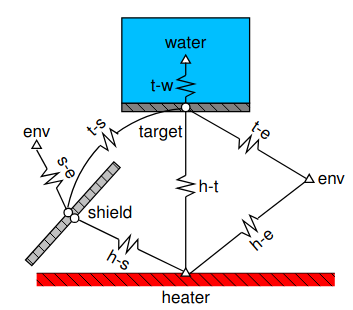

Example taken from "TNSolver: An Open Source Thermal Network Solver for Octave or MATLAB" by Bob Cochran at Thermal & Fluids Analysis Workshop (TFAWS) 2016

Begin Solution Parameters

title = Radiation Heat Transfer Experiment - Black Target

type = steady

nonlinear convergence = 1.0e-8

maximum nonlinear iterations = 50

End Solution Parameters

Begin Conductors

! Conduction through the beaker wall, 0.1" thick pyrex glass

t-bbin conduction targ bbin 0.14 0.00254 0.024829 ! k L A

! Convection from beaker to water

! label type nd_i nd_j mat L A

t-w ENChplateup bbin water water 0.04445 0.02483

! Convection from target to air

! label type nd_i nd_j mat L A

t-air ENChplatedown targ env air 0.0889 0.0248

! Convection from outer shield to air

! label type nd_i nd_j mat H L theta A

s-air ENCiplateup s_out env air 0.0508 0.0508 48.0 0.056439

! Conduction from inner to outer side of shield

shield conduction s_in s_out steel 0.001 0.056439

End Conductors

Begin Radiation Enclosure

! surf emiss A Fij

htr 0.92 0.06701 0.0 0.1264 0.68415 0.0 0.1893

targ 0.95 0.02482 0.34132 0.0 0.00603 0.1031 0.5494

s_in 0.28 0.05643 0.81231 0.00265 0.12278 0.0 0.0622

s_out 0.28 0.05643 0.0 0.0453 0.0 0.0 0.9546

env 1.00 0.11840 0.10711 0.1151 0.02965 0.4547 0.2933

End Radiation Enclosure

Begin Boundary Conditions

! type Tb Node(s)

fixed_T 23.0 env

fixed_T 88.3 water

fixed_T 515.0 htr

End Boundary Conditions

Output from *.rst file:

time = 0 bbin 93.4466 env 23 htr 515 s_in 272.032 s_out 271.956 targ 175.252 water 88.3

Fin with force convection and thermal radiation

[Tc]

|

.,,,,,,,,,,,,,,,,,,,*,,,,,,,,,,,,,,,,,,,. [Tc]

| | | | | | |

| | | | | | |

[base]-----[1]-----[2]-----[3]-----[4]-----[5]-----[6]-----[tip]

| | | | | | |

| | | | | | |

```````````````````|``````````````````` [Tr]

[Tr]

! Fin Experiment Model - Aluminum fin - Forced convection

Begin Solution Parameters

title = Aluminum Fin - Forced Convection

type = steady

nonlinear convergence = 1.0e-8

maximum nonlinear iterations = 15

End Solution Parameters

Begin Conductors

! label type nd_i nd_j k L A

100 conduction base 1 167.0 0.030 0.000127

101 conduction 1 2 167.0 0.025 0.000127

102 conduction 2 3 167.0 0.045 0.000127

103 conduction 3 4 167.0 0.070 0.000127

104 conduction 4 5 167.0 0.050 0.000127

105 conduction 5 6 167.0 0.063 0.000127

106 conduction 6 tip 167.0 0.002 0.000127

! label type nd_i nd_j mat Vel D A

121 EFCcyl 1 Tc air 3.7 0.0127 0.00170

122 EFCcyl 2 Tc air 3.7 0.0127 0.00140

123 EFCcyl 3 Tc air 3.7 0.0127 0.00229

124 EFCcyl 4 Tc air 3.7 0.0127 0.00239

125 EFCcyl 5 Tc air 3.7 0.0127 0.00225

126 EFCcyl 6 Tc air 3.7 0.0127 0.00134

127 EFCcyl tip Tc air 3.7 0.0127 0.00013

! label type nd_i nd_j emissivity A

221 surfrad 1 Tr 0.09 0.001696

222 surfrad 2 Tr 0.09 0.001396

223 surfrad 3 Tr 0.09 0.002294

224 surfrad 4 Tr 0.09 0.002394

225 surfrad 5 Tr 0.09 0.002254

226 surfrad 6 Tr 0.09 0.001337

227 surfrad tip Tr 0.09 0.000127

End Conductors

Begin Boundary Conditions

! type Tb Node(s)

fixed_T 25.0 Tc

fixed_T 25.0 Tr

fixed_T 55.8 base

End Boundary Conditions

Example of Composite Walls

.---------,----------------------,-----------,

| | | |

| | kB | |

| | | |

[TIN] kA [1]--------------------[2] kD [TOUT]

| | | |

| | kC | |

|_________|______________________|___________|

Option-1 of thermal network

|````````|

| |

[TIN]-------[1] [2]------[TOUT]

| |

| |

````````

! label type node-1 node-2 parameters (k, L, A)

100 conduction Tin 1 1.0 1.0 2.0

101 conduction 1 2 2.0 3.0 1.0

102 conduction 1 2 2.0 3.0 1.0

103 conduction 2 Tout 1.0 1.0 2.0

Option-2: Two parallel paths

|`````````[1]``````[2]````````|

| |

[TIN] [TOUT]

| |

| |

`````````[3]``````[4]````````

! label type node-1 node-2 parameters (k, L, A)

100 conduction Tin 1 1.0 1.0 1.0

101 conduction 1 2 2.0 3.0 1.0

102 conduction 2 Tout 1.0 1.0 1.0

103 conduction Tin 3 1.0 1.0 1.0

104 conduction 3 4 2.0 3.0 1.0

105 conduction 4 Tout 1.0 1.0 1.0

Fluid Network Solver

Many of the concepts used in thermal network solver can also be used in fluid network solver (without heat transfer). For incompressible flows (constant density), from continuity for node 'i' and connected nodes designated as 'j': \[\sum\limits_{j}Q_{ij} = Q_D \] where QD is flow demand (inflow or outflow) at node 'i'.Major difference is in the basic definitions though: ΔT = Q. RTH and ΔP = Q2 * RHD

If a flow network contains NN junctions (or nodes) then NN-1 independent continuity equations in the form given above can be written. A flow resistance network consisting of NN nodes (junctions) and NL non-overlapping loops formed by NP resistances, will satisfy the equation NP = (NN - 1) · NL. From energy equations in terms of head losses and NL number of independent loops, for loop 'i': \[\sum \limits_{j}\Delta h_{j}^i = 0 \] The head loss for a flow resistance is typically given as Δh = ξ·Qn (n = 2 for most cases): \[\sum \limits_{j}\xi_j \cdot Q_{j}^n = 0 \] Solving for the NP unknown volumetric flow rates in the NP flow resistances (pipes) of a network, as many number of equations must be derived. Most widely used method for solving fluid flow networks is the Hardy Cross method which is an adaptation of the Newton-Raphson method which solves one equation at a time before proceeding to the next equation during each iteration instead of solving all equations simultaneously. The steps used in Hardy-Cross method are as follows:- Make an initial guess of flow rates in each flow resistors

- Compute the sum of head losses around a loop of the network taking into account direction of flow: \(\sum \limits_{j}^{LOOP}\xi_j \cdot Q_{j}^n \)

- Calculate the sum of absolute values of differential of head loss equation: \(\sum \limits_{j}^{LOOP}\lvert n\cdot \xi_j \cdot Q_{j}^{n-1} \rvert \)

- Compute change in flow ΔQ by dividing results from step-2 by that of step-3.

- Repeat steps 2 to 4 for each loop in the flow network

- Repeat steps 2 to 5 iteratively until ΔQ computed during an iteration reduce below certain pre-defined tolerance (convergence criteria).

[4]```````[5]``````[6]

| |

[1]-----[2]-----[3] [7]

| |

[8]-------[9]------[10]

|

[12]------[11]-----[13]

| |

[17]-----------[14] |

| |

[15]----------------[16]

And the input file can be of the following format where (like in thermal network solver) of '0' implies unknown (to be calculated). Note that NP = (NN - 1) · NL does not hold true here. For initial version of the solver, all nodes are assumed to be at same height. The hydraulic diameter, length and friction factor can be specified for each branch to calculate flow resistances. A friction factor of value 0 implies it is calculated as per empirical correlations, here correlations as per Swamee-Jain is used. A value of zero for hydraulic resistance implies that it needs to be calculated as per

\[R_1 = \frac{\Delta P}{\rho Q^2} = f \cdot \frac{L}{D} \cdot \frac{1}{2A^2} = \frac{1}{m^4}\]

\[R_1 = \frac{\Delta P}{\rho Q^2} = f \cdot \frac{8}{\pi^2} \cdot \frac{L}{D^5} = \frac{1}{m^4}\]

\[R_2 = \frac{\Delta h}{Q^2} = f \cdot \frac{8}{\pi^2} \cdot \frac{L}{D^5} = \frac{s^2}{m^3}\]

where A is the reference area or area based on hydraulic diameter. Note that hydraulic diameter DH, and wall roughness are in [mm], branch length L_BRANCH is in [m]. For pipe length 1.0 [m], diameter 250 [mm], to get R = 1.0, f = 1.205E-3

[FLOW RESISTORS BEGIN] R_ID, s_node, e_node, resistance, fric_fac, DH, L_BRANCH, roughness R01, 1, 2, 1.0, 0.02, 20.0, 100.0, 0.045 R02, 2, 3, 2.0, 0.02, 20.0, 100.0, 0.045 R03, 3, 4, 3.0, 0.02, 20.0, 100.0, 0.045 R04, 4, 5, 4.0, 0.02, 20.0, 100.0, 0.045 R05, 5, 6, 5.0, 0.02, 20.0, 100.0, 0.045 R06, 6, 7, 6.0, 0.03, 20.0, 100.0, 0.045 R07, 7, 10, 7.0, 0.02, 20.0, 100.0, 0.045 R08, 9, 10, 8.0, 0.01, 20.0, 100.0, 0.045 R09, 8, 9, 9.0, 0.01, 20.0, 100.0, 0.045 R10, 8, 3, 8.0, 0.01, 20.0, 100.0, 0.045 R11, 9, 11, 7.5, 0.02, 20.0, 100.0, 0.045 R12, 11, 12, 6.0, 0.01, 20.0, 100.0, 0.045 R13, 11, 13, 5.0, 0.01, 20.0, 100.0, 0.045 R14, 12, 14, 4.0, 0.01, 20.0, 100.0, 0.045 R15, 14, 15, 3.0, 0.05, 20.0, 100.0, 0.045 R16, 13, 16, 2.5, 0.01, 20.0, 100.0, 0.045 R17, 15, 16, 2.0, 0.02, 20.0, 100.0, 0.045 R18, 14, 17, 1.0, 0.01, 20.0, 100.0, 0.045 [FLOW RESISTORS END]The nodes (junctions) of specified pressure and losses at junctions such as merging branches can be specified in following section. N_PR is pressure as node, N_SRC is momentum source or sink at the node (typically used at Tee and Y-junctions) - units same as pressure per unit denisty. Q_DMND is the demand (inflow or outflow) at the node, Q_BR is fixed flow through the branch. Note that pressure specified is in units of [J/kg] and not [Pa] - based on definition of flow resistance above.

[NODES BEGIN] NNUM, N_PR, Q_DMND, N_SRC 1, 250, 1.50, 0 17, 0, 0, 0 [NODES END]Branches (hydraulic resistors with known fixed flow rates, or pump/fan curve). The specified flow rates should be in m3/s. The direction of flow should be from Node_i to Node_j. Q_BR acts as the constant in the fan curve C0 + C1*Q + C2*Q2.

[SPECIAL BRANCHES BEGIN]

Node_i, Node_j, Q_BR, C1, C2

13, 16, 0.05, 0, 0

[SPECIAL BRANCHES END]

Java Code to read the text file into dictionaries (data map) and vectors (list) as per pre-defined sections and headers. Sample input file is here.

def calcHydResistance(DH, LN, FF): # Calculate resistance (as per dP/ρ = R * Q^2) in units of [m-4] return (0.8105695 * LN * FF / D**5) # 8*FF*LN/π2/D5

Let's explore a generic branch connected with multiple branches at the two ends.

[m] [n]

| |

| |

Qi---> [i]---------[j] <---Qj

/ \

/ \

[u] [v]

\( Q_i = R_{ij} \cdot (P_i - P_j)^n \text{ if } P_i > P_j\) where n = 1/2 for most of hydraulic elements. \( Q_j = R_{ij} \cdot (P_j - P_i)^n \text{ if } P_j > P_i\). In other words: \( Q_i = R_{ij} \cdot |P_i - P_j|^{n-1} \cdot (P_i - P_j)\) and \( Q_j = R_{ij} \cdot |P_j - P_i|^{n-1} \cdot (P_j - P_i)\). In matrix notation,

\[ \begin{bmatrix} Q_i \\ Q_j \end{bmatrix} = R'\begin{bmatrix} +1 \; \; -1 \\ -1 \; \; +1 \end{bmatrix} \begin{bmatrix} P_i \\ P_j \end{bmatrix} \dots [1] \]

Applying continuity at any interior node i (without mass generation or accumulation at any node, though mass can come in or go out from boundary nodes), a linear system of equations [R]{P'} = {Q*} can be created where vector {P'} is corrected pressure and vector {Q} is the estimated flow rates. This is an alternate formulation of element-by-element solution method which does not require formation of the full coefficient matrix. Conjugate Gradient method of solution can be used to iteratively solve the

linearised equations.

Instead of tracking sign of flow rates (direction), it is easier to use following formulation:

\[Q_{ij} = \frac{P_i - P_j}{|P_i - P_j|} \cdot \sqrt \frac{|P_i - P_j|}{R_{ij}} \dots [2]\] This can be conveniently implements in Python as: Q[i][j] = np.sign(P[i] - P[j]) * math.sqrt(abs(P[i] - P[j])/R[i][j])Another approach is to use SIMPLE-like algorithm used in 3D CFD simulation programs. The "true" pressure and flow rates are defined as \(P = P^{*} + P^{\prime }\) and \(Q = Q^{*} + Q^{\prime }\). By linearizing the momentum equation, the flow correction \(Q_{ij}^{\prime }\) is related to the pressure correction \(P^{\prime }\) by: \(Q_{ij}^{\prime }\approx d_{ij}(P_{i}^{\prime } - P_{j}^{\prime })\) where \(d_{ij}\) is a sensitivity coefficient derived from the derivative of the head loss equation. The quadratic head loss (\(\Delta P = R\cdot Q^{2}\)) is linearised using the derivative [dP/dQ]-1 = \(d = \frac{1}{2R\cdot Q}\)

Step-1: Guess initial values of pressures at nodes

Step-2: Calculate flow rates Q* through each branch using equation: \(P_i - P_j = \frac {Q_{ij}}{|Q_{ij}|} \cdot \xi_{ij}\frac{\rho}{2} \cdot \frac {Q_{ij}^2}{A^2}\) where Q/|Q| is a sign change term that insures that the pressure loss term always opposes the flow direction. For constant density and denoting P ≡ P/ρ, Q* ≡ QNEW = ΔP /(QOLD + ε) / R where R ≡ ξ/2A2 and Qij is the flow from node 'i' to node 'j' with appropriate sign.Step-3: Calculate flow rate correction Q' by differentiating branch pressure drop equation with respect to Qij where \(P'_i - P'_j = \frac {Q_{ij}}{|Q_{ij}|} \cdot R_{ij} \cdot Q_{ij}\)

\[\frac{dP_i}{dQ_{ij}} - \frac{dP_j}{dQ_{ij}} = 2 \cdot R_{ij} \cdot Q_{ij} \] dPi ≡ P'i | dPj ≡ P'j | dQi ≡ Q'i and dQj ≡ Q'j. Qij is flow through branch defined by nodes i and j, Qi is flow through branch number i. \[\frac{P'_i}{Q'_{ij}} - \frac{P'_j}{Q'_{ij}} = 2 \cdot R_{ij} \cdot Q_{ij} \] or \[\frac{P'_i}{\beta_{ij}} - \frac{P'_j}{\beta_{ij}} = Q'_{ij} \dots [3] \] where \[ \beta_{ij} = 2 \cdot R_{ij} \cdot Q_{ij} \] [1/βij] is the 'linearised' pipe conductance and the link to pressure-correction equations. The local slopes of pressure drop vs flow rate curve define linear mapping between pressure corrections to flow corrections (analogous to pressure correction schemes in CFD to enforce mass conservation by linearised momentum-pressure coupling).Step-4: Apply continuity equation at each node, excluding those at boundaries and known pressures to generate system of equation of the form [A]{P'} = {b}. Substitute \(Q_{ij} = Q_{ij}^{*} + Q_{ij}^{\prime }\) into the continuity equation at each node to obtain a system of linear equations for \(P^{\prime }\): \(\sum \limits_{j}d_{ij}(P_{i}^{\prime } - P_{j}^{\prime }) = S_{i} - \sum \limits_{j}Q_{ij}^{*} = b_i\). The right-hand side represents the mass imbalance (residual) at node 'i' and 1/βij ≡ dij

Step-5: Assemble the summation over all interior nodes to form the equation [A] · {P'} = {b} where diagonal terms Aii = Σkdik with 'k' denoting nodes connected to node 'i'. The off-diagonal terms are Aij = -dij where dij = 1/βij

Step-6: Solve for nodal values of P' and update nodal pressures, P = P* + P' and compute flow rates Q*ij

Step-7: Check for convergence of P' and Q* by checking maximum value in vector {b}

Step-8: Go to step-3 if convergence not achieved.

Improve robustness of convergence: Use under-relaxation factor (RF) for pressure correction p = p + RF * p' and limit the value of d when Q is closer to zero by capping 'Q' to small none zero value say 1.0E-5 [units].Newton-Raphson Method for One Non-Linear Equation

xi+1 = xi - f(x) / [∂f/∂x] - The Newton-Raphson method in matrix form to solve systems of non-linear equations, F(X) = 0, iteratively using the formula \(X_{n+1}=X_{n}-[J(X_{n})]^{-1}F(X_{n})\), where {X} is the vector of unknowns / variables, {F(X)} is the vector of functions, and [J(X)] is the Jacobian matrix containing all partial derivatives. At each iteration, it finds the change \(\Delta X=-[J(X_{n})]^{-1}F(X_{n})\) by solving a linear system, then updates the guess \(X_{n+1} = X_{n}+\Delta X\), repeating until convergence. Key Components System of Equations: \[F(X) = \left[\begin{matrix}f_{1}(x_{1},\dots , x_{n})\\ \vdots \\ f_{n}(x_{1},\dots ,x_{n})\end{matrix}\right]=\left[\begin{matrix}0\\ \vdots \\ 0\end{matrix}\right]\] Variables Vector: \[X = \left[\begin{matrix}x_{1}\\ \vdots \\ x_{n}\end{matrix}\right]\] Jacobian Matrix: \[J(X) = \left[\begin{matrix}\frac{\partial f_{1}}{\partial x_{1}}&\dots &\frac{\partial f_{1}}{\partial x_{n}}\\ \vdots &\ddots &\vdots \\ \frac{\partial f_{n}}{\partial x_{1}}&\dots &\frac{\partial f_{n}}{\partial x_{n}}\end{matrix}\right]\] Iteration Formula: \[X_{n+1} = X_{n}-[J(X_{n})]^{-1}F(X_{n})\] or \[X_{n+1} = X_{n} + \Delta X\text{, where }\Delta X = -[J(X_{n})]^{-1}F(X_{n})\]For more explanations, refer to page engcourses-uofa.ca/books/numericalanalysis/nonlinear-systems-of-equations/newton-raphson-method

Example network and coefficient matrix development

(0) (1) (2)

---> [0]---->----[1]----->---[2]---->----[3] --->

| | |

| | |

| \|/(4) \|/(3)

| | |

| | (6) |

(10)\|/ [4]---------->----------[5]

| | |

| | |

| \|/(8) \|/(5)

| | |

| (9) | (7) |

[8]----<----[7]---------<-----------[6] --->

From mass balance at each node:

+q[0] + q[1] + q[2] + q[3] + q[4] + q[5] + q[6] + q[7] + q[8] + q[9] + q[10] = b

--------------------------------------------------------------------------------

+q[0] + + q[10] = qb[0]

-q[0] + q[1] + q[4] = 0

- q[1] + q[2] = 0

- q[2] + q[3] = qb[3]

- q[4] + q[6] + q[8] = 0

- q[3] + q[5] - q[6] = 0

- q[5] + q[7] = qb[6]

- q[7] - q[8] + q[9] = 0

- q[9] - q[10] = 0

The equations in matrix form is:

0 1 2 3 4 5 6 7 8 9 10

Node _ Resistor Numbers _

0 | +1 0 0 0 0 0 0 0 0 0 +1 | {q[0] } = {qb[0]}

1 | -1 +1 0 0 +1 0 0 0 0 0 0 | {q[1] } = { 0 }

2 | 0 -1 +1 0 0 0 0 0 0 0 0 | {q[2] } = { 0 }

3 | 0 0 -1 +1 0 0 0 0 0 0 0 | {q[3] } = {qb[3]}

4 | 0 0 0 0 -1 0 +1 0 +1 0 0 | {q[4] } = { 0 }

5 | 0 0 0 -1 0 +1 -1 0 0 0 0 | {q[5] } = { 0 }

6 | 0 0 0 0 0 -1 0 +1 0 0 0 | {q[6] } = {qb[6]}

7 | 0 0 0 0 0 0 0 -1 -1 +1 0 | {q[7] } = { 0 }

8 | 0 0 0 0 0 0 0 0 0 -1 -1 | {q[8] } = { 0 }

`` `` {q[9] }

{q[10]}

How will the system of equations and matrix formulation change if a resistors say (6) is given fixed flow conditions? In other words, q[6] is known. Resistor (6) is defined by nodes [4] and [5] and hence q[6] term shall appear in mass balance equations for nodes [4] and [5]. Note that indices for nodes and hydraulic resistors follow different sequences.

The equations in matrix form shall translate into the following format:

0 1 2 3 4 5 6 7 8 9 10

Node _ Resistor Numbers _

0 | +1 0 0 0 0 0 0 0 0 0 +1 | {q[0] } = {qb[0]}

1 | -1 +1 0 0 +1 0 0 0 0 0 0 | {q[1] } = { 0 }

2 | 0 -1 +1 0 0 0 0 0 0 0 0 | {q[2] } = { 0 }

3 | 0 0 -1 +1 0 0 0 0 0 0 0 | {q[3] } = {qb[3]}

4 | 0 0 0 0 -1 0 (0) 0 +1 0 0 | {q[4] } = {-q[6]}

5 | 0 0 0 -1 0 +1 (0) 0 0 0 0 | {q[5] } = {+q[6]}

6 | 0 0 0 0 0 -1 0 +1 0 0 0 | {q[6] } = {qb[6]}

7 | 0 0 0 0 0 0 0 -1 -1 +1 0 | {q[7] } = { 0 }

8 | 0 0 0 0 0 0 0 0 0 -1 -1 | {q[8] } = { 0 }

`` `` {q[9] }

{q[10]}

The variable q[6] shall not participate in iterative computation and hence A[u, NP_FF] = 0.0 and A[v, NP_FF] = 0 where 'u' and 'v' are the nodes defining the fixed flow branch number NP_FF. In this example, u = 4, v = 5 and NP_FF = 6.

The matrix equation in pressure form after linearisation Q[k] = (p[i] - p[j]) / R[k] / Q[k]

0 1 2 3 4 5 6 7 8 9 10 { dp } / {REFF} = { b }

Node _ Resistor Numbers _

0 | +1 0 0 0 0 0 0 0 0 0 +1 | {p[0] - p[1]}/R[ 0]/Q[ 0] = {qb[0]}

1 | -1 +1 0 0 +1 0 0 0 0 0 0 | {p[1] - p[2]}/R[ 1]/Q[ 1] = { 0 }

2 | 0 -1 +1 0 0 0 0 0 0 0 0 | {p[2] - p[3]}/R[ 2]/Q[ 2] = { 0 }

3 | 0 0 -1 +1 0 0 0 0 0 0 0 | {p[3] - p[5]}/R[ 3]/Q[ 3] = {qb[3]}

4 | 0 0 0 0 -1 0 +1 0 +1 0 0 | {p[1] - p[4]}/R[ 4]/Q[ 4] = { 0 }

5 | 0 0 0 -1 0 +1 -1 0 0 0 0 | {p[5] - p[6]}/R[ 5]/Q[ 5] = { 0 }

6 | 0 0 0 0 0 -1 0 +1 0 0 0 | {p[4] - p[5]}/R[ 6]/Q[ 6] = {qb[6]}

7 | 0 0 0 0 0 0 0 -1 -1 +1 0 | {p[6] - p[7]}/R[ 7]/Q[ 7] = { 0 }

8 | 0 0 0 0 0 0 0 0 0 -1 -1 | {p[4] - p[7]}/R[ 8]/Q[ 8] = { 0 }

`` `` {p[7] - p[8]}/R[ 9]/Q[ 9]

{p[0] - p[8]}/R[10]/Q[10]

_ _

0 | +1 0 0 0 0 0 0 0 0 0 +1 | {p[0] - p[1]} / REFF00 = {qb[0]}

1 | -1 +1 0 0 +1 0 0 0 0 0 0 | {p[1] - p[2]} / REFF01 = { 0 }

2 | 0 -1 +1 0 0 0 0 0 0 0 0 | {p[2] - p[3]} / REFF02 = { 0 }

3 | 0 0 -1 +1 0 0 0 0 0 0 0 | {p[3] - p[5]} / REFF03 = {qb[3]}

4 | 0 0 0 0 -1 0 +1 0 +1 0 0 | {p[1] - p[4]} / REFF04 = { 0 }

5 | 0 0 0 -1 0 +1 -1 0 0 0 0 | {p[5] - p[6]} / REFF05 = { 0 }

6 | 0 0 0 0 0 -1 0 +1 0 0 0 | {p[4] - p[5]} / REFF06 = {qb[6]}

7 | 0 0 0 0 0 0 0 -1 -1 +1 0 | {p[6] - p[7]} / REFF07 = { 0 }

8 | 0 0 0 0 0 0 0 0 0 -1 -1 | {p[4] - p[7]} / REFF08 = { 0 }

`` `` {p[7] - p[8]} / REFF09

{p[0] - p[8]} / REFF10

_ 0 1 2 3 4 5 6 7 8 _

| +1 -1 0 0 0 0 0 0 0 | {p[0]}

| 0 +1 -1 0 0 0 0 0 0 | {p[1]}

| 0 0 +1 -1 0 0 0 0 0 | {p[2]}

| 0 0 0 +1 0 -1 0 0 0 | {p[3]}

{dp} = | 0 +1 0 0 -1 0 0 0 0 | {p[4]} = [BT] * {p}

| 0 0 0 0 0 +1 -1 0 0 | {p[5]}

| 0 0 0 0 +1 -1 0 0 0 | {p[6]}

| 0 0 0 0 0 0 +1 -1 0 | {p[7]}

| 0 0 0 0 +1 0 0 -1 0 | {p[8]}

| 0 0 0 0 0 0 0 +1 -1 |

| +1 0 0 0 0 0 0 0 -1 |

`` ``

Here, REFF = R*Q. Note that vector {dp} can be formulated as [BT].{p} where {p} = {p[0] p[1] ... p[10]}T and hence {Q*} = {Δp}/{RQ} where right hand side is element-wise division.

As described in equation [3] above, it is pressure correction that is usually solved. The summary of steps in matrix notation is described again. Here · denotes matrix multiplication as per '@' operator in Python. * and / are element-wise multiplication and division of vectors.

- From continuity: [B] · {Q} = {Qd} where {Qd} is demand (outflow) or supply (inflow) at nodes

- As derived above, {Q*} = [B]T · {dp} / {REFF} where {REFF} = {R} · {Q*}

- As per linearisation: Q = Q* + Q' and hence {Q} = {Q*} + {Q'} where {Q*} is guessed or values calculated during iterations. Thus: residual vector or mass imbalance vector, [B]·{Q* + Q'} = {Qd}

- From iterative solution: {b} = {Qd} - [B] · {Q*}

- [B] · {Q'} = {Qd} - [B] · {Q*}

- [B] · {Q'} = {b}

- From equation (3) above: {Q'} = [1/β] · [dP'] = [1/β] · [B]T · {P'}

- From equations [B] · {Q'} = {b} and {Q'} = [1/β] · [B]T · {P'}

- [B] · [1/β] · [B]T · {P'} = {b}

- [Ap] · {P'} = {b}

- [Ap] = [B] · [1/β] · [B]T

- Note that {b} = - [B] · {Q*} where there is no external demand or supply at internal nodes.

Example Validation Cases

All resistances of equal diameters, density of working fluid = 1.25 [kg/m2 constant for all nodes. Resistances are in units of \(\frac{\Delta{P}}{\rho \cdot Q^2} = \frac{kg}{m.s^2}\cdot \frac{m^3}{kg} \cdot \frac{s^2}{m^6} = \frac{1}{m^4} \)Validation Case-1

[0]-------[1]-------[2]-------[3] R_ID s_node e_node RHYD R1 0 1 3 R2 1 2 5 R3 2 3 8Specified pressure [Pa] nodes:

Node N_PR 0 100 3 0Flow through each branch = (100 / 16)0.5 = 2.5 [m3/s] and pressure drops are [18.75, 31.25, 50.0] Pa for each branch and hence node pressures are [100, 81.25, 50.0, 0.0] Pa.

Validation Case-2

[0]-------[1]-------[2]-------[3]

|

|

[4]

R_ID s_node e_node RHYD

R1 0 1 3

R2 1 2 5

R3 2 3 8

R3 2 4 2

Specified pressure [Pa] nodes:

Node N_PR 0 100 3 0 4 0For hydraulic resistance in parallel: \[\sqrt\frac{1}{R^{ij}_{EQ}} = \sqrt\frac{1}{R_i} + \sqrt\frac{1}{R_j} \] Nodes 3 and 4 are in parallel with respect to node 2. Overall resistance of the system = 3 + 5 + 0.889 = 8.889 and thus incoming flow at node 1 is (100 / 8.889)0.5 = 3.354 [m3/s] and pressure drops through series branches are [33.75, 56.25] Pa. The node 1 is at 100 - 33.75 = 66.25 [Pa] and node 2 is at 100 - [33.75 + 56.25] = 10.0 [Pa] and flow through branches 2-3 and 2-4 are [1.118, 2.236] [m3/s].

Solve "Validation Case-1" iteratively using manual (hand-calculation) method.

Step-1:

Initial value of p at nodes: [100, 0, 0, 0]Step-2:

Incidence Matrix: B[s_node, i] = +1 and B[e_node, i] = -1 for i = 0 to NP-1 ---as per assumption that flow along the left node to right node used to define branches (hydraulic resistances) is positive and flow in opposite direction is negative. If a node appears only as start node, it is assumed to have positive flow (flow shall enter into that node) and if a node appears only as end node, the flow is assumed to be negative (flow shall exit through that node).[[+1 0 0] [-1 +1 0] [ 0 -1 +1] [ 0 0 -1]]Each row of the incidence matrix defines the status of that node and node number of connected branches.

Step-3:

Initial flow rates through each branch: Q* = [5.770, 0.001, 0.001] using formula Q=[ΔP/R]1/2 or Q * Q = [ΔP/R] and hence Q = [ΔP/R/Q] then calculate mass imbalance for each node, {b} = [5.770 -5.770, 0.0, 0.0]Step-4:

Calculate pressure correction equation (coefficient matrix) - the right hand side of the equation is nothing but {b} which has unit of flow rate.

0.5 / (R[0][1] * Q[0][1]) * (P0' - P1') = Q*01

0.5 / (R[1][2] * Q[1][2]) * (P1' - P2') = Q*12

0.5 / (R[2][3] * Q[2][3]) * (P2' - P3') = Q*23

or

1/β01|+1 -1 0 0| |P0'| |b0|

1/β12| 0 +1 -1 0| |P1'| = |b1|

1/β23| 0 0 +1 -1| |P2'| |b2|

|P3'|

{βij} = (0.0289 = 0.5/5.770/3 100.0 = 0.5/0.001/5 62.5 = 0.5/0.001/8)

[A] =

[[ 1 0 0 0 ] [ 0 100.03 -100.0 0 ] [ 0 -100.00 162.5 0 ] [ 0 0 0 1 ]]

Step-5:

Solver p_corr = np.linalg.solve(A, b) which gives p_corr = [ 0 -0.150 -0.092 0] - note that pressure correction is negative and it will make intermediate pressure values at nodes beyond the lower and upper limits of boundary conditions. This is an example where {b} and [A] are calculated incorrectly. The iterations using Python code indeed diverged. One likely reason might be that the rows and columns corresponding for specified node pressure are part of coefficient matrix. Second, p_corr = np.linalg.solve(A, -b) should be used instead of p_corr = np.linalg.solve(A, b). In this case, p_corr = np.linalg.solve(A, -b) worked with same coefficient matrix [A] defined above. In MATLAB, mldivide (the backslash operator, A\B) solves the system of linear equations [A]{x} = {b} for vector {x}.Few properties of matrix multiplications

Multiplying a matrix by a diagonal matrix scales its rows or columns: left-multiplication (Diagonal Matrix * Base Matrix) scales each row of the matrix by the corresponding diagonal element, while right-multiplication (Base Matrix * Diagonal Matrix) scales each column by the corresponding diagonal element, effectively transforming the matrix without changing its dimensions.Multiplying a matrix [A] by a diagonal matrix [D] and then by the transpose of the first matrix [AT] results in a new symmetric matrix, where the elements across the main diagonal are equal, effectively scaling the rows of [A] by diagonal elements before combining them with the scaled columns of [AT].

Associativity of multiplication: A · (B · C) = (A · B) · C

Basic Fluid Network Solver: Both the node pressures and flow rates though branches match the hand calculations for the "Validation Case-1". You may test the following code for your application and let me know cases where it fails.

import numpy as np

def tupleToList(list_of_tuples):

'''

Return the length of unique items in a tuple defining branches

'''

list_1, list_2 = [], []

for t in list_of_tuples:

list_1.append(t[0])

list_2.append(t[1])

unique_list = list(set(list(set(list_1)) + list(set(list_2))))

unique_list.sort()

return len(unique_list), list_1, list_2

def pipeNetwork(pipes, pr_bc, alpha_p=0.5, alpha_q=0.7, max_iter=500, tol=1e-5):

'''

SIMPLE algorithm for arbitrary pipe networks with non-linear resistances

and multiple pressure boundary conditions. Parameters are:

pipes: list of (m, n, R) - Pipe from m -> n with resistance R

pr_bc: dictionary - {node_index: pressure_value}

'''

eps = 1e-5

Np = len(pipes)

nn_nodes, ni, nj = tupleToList(pipes)

nn_uknown = nn_nodes - len(pr_bc.items())

# Incidence matrix

B = np.zeros((nn_nodes, Np)) # N_nodes x N_branch = rows x cols

R = np.zeros(Np)

# Initial guess for pressures at nodes

p = np.ones(nn_nodes)

for node, val in pr_bc.items():

p[node] = val

Q = np.ones(Np) * 0.001 # small non-zero initial flow

for i, (m, n, Ri) in enumerate(pipes):

B[m, i] = +1.0

B[n, i] = -1.0

R[i] = Ri

if p[m] - p[n] != 0:

Q[i] = np.sign(p[m] - p[n]) * np.sqrt(abs(p[m] - p[n]) / R[i])

# Start SIMPLE-type iterations

for iter in range(max_iter):

# 1. Update effective resistance (non-linearity)

R_eff = R * np.abs(Q) + eps

# 2. Momentum predictor

dp = B.T @ p

Q_star = dp / R_eff # Q * Q = dp/R, Q = dp / [R * Q] = dp/R_eff

# 3. Mass imbalance

b = B @ Q_star

# 4. Pressure correction system: dp/dq = 2RQ = 0.5/R_eff

d = 0.5 / R_eff

Ap = B @ np.diag(d) @ B.T

# Apply pressure boundary conditions

for node, val in pr_bc.items():

Ap[node, :] = 0.0

Ap[:, node] = 0.0

Ap[node, node] = 1.0

b[node] = 0.0

# 5. Solve pressure correction: "source term" is the mass imbalance

p_corr = np.linalg.solve(Ap, -b)

# 6. Update pressures

p = p + alpha_p * p_corr

for node, val in pr_bc.items():

p[node] = val

# 7. Correct flows

for i, (m, n, Ri) in enumerate(pipes):

if p[m] - p[n] != 0:

Q[i] = np.sign(p[m] - p[n]) * np.sqrt(abs(p[m] - p[n]) / R[i])

# 8. Check convergence: return node connectivity, node pressure, flow rates

if np.max(np.abs(b)) < tol:

print(f"Converged in {iter + 1} iterations.")

return ni, nj, p, Q

# Print divergence and return 'None'

print("SIMPLE did not converge!")

return ni, nj, None, None

pipes = [(0, 1, 3.0), (1, 2, 5.0), (2, 3, 8.0), (2, 4, 2.0)]

pr_bc = {0: 100.0, 3: 0.0, 4: 0.0}

ni, nj, nodeP, Qdot = pipeNetwork(pipes=pipes, pr_bc=pr_bc, max_iter=100)

if nodeP is not None:

print("-" * 50)

print("All values are in chosen unit of pressure and [m^3/s]")

print("Node pressures:")

for index, value in enumerate(nodeP, start=1):

print(f"{index}: {value:8.2f}")

if Qdot is not None:

print("-" * 50)

print("Flow through pipe branches:")

for index, value in enumerate(Qdot):

print(f" {ni[index]} -> {nj[index]} = {value:6.3f} |", end="")

print("\n")

Here pipe or branch data is represented as tuple (as definition of branch required > 2 variables) and node data as dictionaries (key-value pair can be used to define nodes). This code is part of category known as Gradient Method because it contains gradient of pressures in the pipe branches. The flow correction is proportional to the negative gradient of energy (pressure) imbalance. Ap = B @ np.diag(d) @ B.T is analogous to a Hessian matrix. Due to symmetry, positive definite and sparse nature of coefficient matrix, algorithm is numerically strong (fast and relatively robust).

This code does not provide option to specify fixed flow rate through a branch. The code solves incompressible flow (constant density) and pressure is in reality specific energy [J/kg] - where hydraulic resistance is defined ΔP/ρ = R.Q2. There are some constraint to this simple program: all boundary nodes (those connected with only one other node) has to be specified pressure boundary conditions, even if it is zero. The interior nodes can have known pressures. Pump or fans cannot be modeled (specifying two nodes with fixed pressure increase shall not work).How to implement inflow / outflow nodes and fixed flow resistors?

Note that two boundary nodes connected to an internal node should not have different boundary conditions such as fixed pressure on one and fixed outflow on another. The equation ΔP = R.Q2 will not satisfy on both the branches.To implement inflow or outflow boundary conditions: update vector {b} in SIMPLE iteration such that b[i] = b[i] - Q[i] for node 'i' where Q is positive when flow enters into the flow network through that node. A check is required to ensure same boundary node is not specified pressure as well as inflow / outflow value.

To implement flow demand and supply at nodes, flow rates through branches do not need to be directly adjusted to meet demand. Instead, 'demand' modifies node continuity equation and solver should automatically adjust branch flows using head changes. Once residuals (vector 'b' above) has been calculated for each node without considering demand as each node, create a loop over all nodes and update values of b[i] based on flow demand and sign convention adopted (outflow + or -).For branches with fixed flow rates, update flow correction section in SIMPLE iteration as per following conditions. Here ff_resistances is the list of tuples defining start node, end node and fixed flow rate values. Let's assume node j and k constitute the branch with fixed flow - these nodes cannot be the boundary node (else it will contradict the boundary conditions at these nodes).

(j) (k) (m)

-----[a]-------[u]--------[v]--------[b]-------

| |

(r)| |(s)

| |

[c] [d]

-q[j] + q[k] + q[c] = 0

- q[k] + q[s] + q[m] = 0

or

-q[j] + q[c] = -q[k]

q[s] + q[m] = +q[k]

Practically, the nodes defining both the fixed flow branch and pressure jump or fan branch behave like boundary nodes. In case of fixed flow branch, the pressures at node 'u' and node 'v' are decided by the upstream and downstream conditions respectively where outflow at 'u' = inflow at 'v', the pressure drop through fixed-flow branch has no practical value.

In case of fixed flow branch, the incidence matrix needs to be updated as B[u, k] = 0.0 = B[v, k] where 'k' is the branch number defined above. Additionally, the "Flow Correction" section needs to be added with following conditions.

if u == m and v == n: Q[i] = Q_k for k, (u, v, Q_k) in enumerate(ff_branches): b[u] = b[u] + Q_k b[v] = b[v] - Q_kIn case of pressure jump boundary conditions (which implies a fixed pressure difference exists between two nodes regardless of flow), outflow at 'u' = inflow at 'v' and p[v] = p[u] + Δp. For pressure jump or fan boundary conditions, it is mandatory to use two-branched nodes (those connected with exactly two branches) such as -----[u]---Δp---[v]----- The method requires to find the branch numbers connected to nodes 'u' and 'v' and apply same flow rates to all the 3 branches in addition to p[v] = p[u] + Δp. The flow through the branch defining the pressure jump does not need to be solved same as in fixed-flow branch case. Since pressure of downstream node is known with respect to upstream node, the pressure at downstream node does not need to be solved a part of matrix inversion.

(j) (k) (m)

-----[a]-------[u]--------[v]--------[b]-------

-q[j] + q[k] = 0

- q[k] + q[m] = 0

q[j] = +q[k]

q[m] = +q[k]

For better convergence, use q[k] = (q[j] + q[m])/2.0 and the flow rate calculation for branch 'j' and 'm' needs an update on sign convention for pressure drop.

To implement a second order polynomial for fans where p[v] = p[u] + C0 + C1 * Q[k] + C2 * Q[k]**2, method similar to pressure jump can be updated by adding C1 * Q[k] + C2 * Q[k]**2 as C0 is already modeled in pressure jump.

Calculate resistance based on hydraulic diameter, flow rate and roughness: if the flow resistance is specified as zero, a function can be used to calculate friction factor based on empirical correlations and then calculate hydraulic resistance.

The formula is \[f = \frac{0.25}{\left[\log _{10}\left(\frac{\epsilon }{3.7D} + \frac{5.74}{\text{Re}^{0.9}}\right)\right]^{2}}\] where ε is absolute roughness, D is pipe diameter, and Re is the Reynolds number.def ffSwameeJain(dia, e, Re): return 0.25 / (math.log10(e / 3.7 / dia + 5.74 / Re**0.9))**2The comparison between iterative (implicit) Colebrook-White formula and non-iterative (explicit) Swamee-Jain correlation (at roughness height 0.045) is shown below ↴

Checks for User Inputs: some basic checks are necessary to ensure user inputs are as per expected format. Checks like duplicate branch, same branch with nodes in reverse order, missing node (branch defined by only one node), two different type of boundary conditions defined for same node and node number in boundary conditions not defined in the branch definitions can be easily done in few lines of code.

The printable version of method described above can be accessed here.

Picard-type element (pipe-based) iterations are another algorithm to solve pipe networks which avoid full Newton-Raphson type Jacobians and instead solve a linearised system using updated element conductances at every outer iteration.Quality Assurance of Flow Network Solvers

One approach to validate the output is to check the results by switching boundary conditions at same node. With node-0 applied to 100 [Pa] pressure for validation case-2 described above, the calculated values are summarized below. All boundary nodes are set to pressure value of 0 [Pa] unless a non-zero value is specified in dictionary pr_bc.

Case with pressure boundary conditions - no inflow/outflow:

pipes = [(0, 1, 3.0), (1, 2, 5.0), (2, 3, 8.0), (2, 4, 2.0)]

pr_bc = {0: 100}

All values are in [J/kg] and [m^3/s]

Node pressures:

0: 100.00

1: 66.25

2: 10.00

3: 0.00

4: 0.00

--------------------------------------------------

Flow through pipe branches:

0 -> 1 = 3.3541 | 1 -> 2 = 3.3541 | 2 -> 3 = 1.1180 | 2 -> 4 = 2.2361 |

Case with outlet pressure boundary and inflow:

pipes = [(0, 1, 3.0), (1, 2, 5.0), (2, 3, 8.0), (2, 4, 2.0)]

pr_bc = {}

ff_bc = {0: 3.354}

The output is:

All values are in [J/kg] and [m^3/s] Node pressures: 0: 99.99 1: 66.25 2: 10.00 3: 0.00 4: 0.00 -------------------------------------------------- Flow through pipe branches: 0 -> 1 = 3.3540 | 1 -> 2 = 3.3540 | 2 -> 3 = 1.1180 | 2 -> 4 = 2.2360 |Case with pressure boundary conditions and fixed flow branch:

Inputs:

pipes = [(0, 1, 3.0), (1, 2, 5.0), (2, 3, 8.0), (2, 4, 2.0), (3, 5, 1.0)]

pr_bc = {0:100, 5:0} # Nodes with pressure boundary conditions

ff_bc = {} # Inflow / outflow nodes

ff_branches = [(2, 3, 2.5)]

Results:

All values are in [J/kg] and [m^3/s]

Node pressures:

0: 100.00

1: 63.25

2: 2.00

3: 6.25

4: 0.00

5: 0.00

--------------------------------------------------

Flow through pipe branches:

0 -> 1 = 3.5000 | 1 -> 2 = 3.5000 | 2 -> 3 = 2.5000 | 2 -> 4 = 1.0000 |

3 -> 5 = 2.5000 |

Flow network with fixed-flow and fan boundary conditions

pipes = [(0, 1, 11.95), (1, 2, 5.0), (2, 3, 8.0), (2, 4, 2.0),

(3, 5, 1.0), (1, 6, 7.5), (6, 7, 1.0), (7, 8, 5.0)]

ff_rs = [(2, 3, 1.0)] # Fixed flow branch

pj_rs = [(6, 7, 20)] # Pressure jump branch

pr_bc = {0:100}

PFAN = 20

6-----------7-----------8

|

0-----1-----2-----4

|

3

|

5

Results are:

Converged in 22 iterations -------------------------------------------------- All values are in [J/kg] and [m^3/s] Node pressures: 0: 100.00 1: 8.20 2: 0.15 3: 1.00 4: 0.00 5: 0.00 6: -8.72 7: 11.28 8: 0.00 -------------------------------------------------- Flow through pipe branches: 0 -> 1 = 2.7716 | 1 -> 2 = 1.2695 | 2 -> 3 = 1.0000 | 2 -> 4 = 0.2695 | 3 -> 5 = 1.0000 | 1 -> 6 = 1.5021 | 6 -> 7 = 1.5021 | 7 -> 8 = 1.5021 |

One of the simplest example to test the solver on pipe network with pressure jump branch can be one shown below.

p=100 dp=20 p=0

0---------1---------2---------3

R=3 R=1 R=5

Flow rate through each branch = [120/8]0.5 = 3.873 [units]. Pressure values at nodes shall be [100]------[55]------[75]------[0]. Here, the pressure jump acts as pressure booster for node 2. If the pressure jump direction is reversed, flow rate reduces to [80/8]0.5 = 3.162 [units] and pressure values at nodes shall be [100]-----[70]-----[50]-----[0].

Another validation case from Hydraulics of Pipeline Systems, Example problem 4.6 is described below. The pipe network has 2 pumps, two globe valves and a meter and fluid is water at 10 [°C].

0.030

/|\

|

6----(7)----1-----(1)----2------> 0.080

170 [m] | | \

| | \

(4) (2) (5)

| | \

| | \

7----(8)----4-----(3)----3----(6)---5---> 0.080

200 [m] |

|

\|/

0.050

Branch Diameter [mm] Length [m]

1 200 500

2 200 300

3 200 500

4 200 300

5 200 500

6 200 500

7 250 300

8 250 300

Branch number and flow rates [m3/s]: 1 → 2: 0.103, 3 → 2: 0.014, 4 → 3: 0.107, 4 → 1: 0.078, 2 → 5: 0.037, 3 → 5: 0.043, 6 → 1: 0.055, 7 → 4: 0.185

Example: 3-Reservoirs System, here \(R=\frac{8fL}{\pi^{2}gD^{5}}\)

Goal is to find the flow in each of the three pipes and the pressure at the junction '4' and pressure is expressed as height of water column.

| |

| [1] | | |

|_______| | [3] |

\ /``````|_______|

\ /

\ /

\ /

\ / | |

\ / | [2] |

[4]*---------------|_______|

\

\

===========---=====================Ground==========

H = (70 80 100 ?) [m], friction factor = 0.015

L[1, 4] = 5000 [m], L[2, 4] = 3000 [m], L[3, 4] = 4000 [m]

D[1, 4] = 0.60 [m], D[2, 4] = 0.80 [m], D[3, 4] = 1.20 [m]

R[1, 4] = 72.7266, R[2, 4] = 11.3517 , R[3, 4] = 1.99316

Pipe [1, 4]: H[1] - H[4] = R[1, 4] * Q[1, 4] * |Q[1, 4]|

Pipe [2, 4]: H[2] - H[4] = R[2, 4] * Q[2, 4] * |Q[2, 4]|

Pipe [3, 4]: H[3] - H[4] = R[3, 4] * Q[3, 4] * |Q[3, 4]|

Pipe [1, 4]: 70 = H[4] + 72.7266 * Q[1, 4] * |Q[1, 4]|

Pipe [2, 4]: 80 = H[4] + 1.99316 * Q[2, 4] * |Q[2, 4]|